Copper foil processing is a crucial aspect of high-frequency transformer design and application. With the increasing demand for high-frequency transformers in various industries such as telecommunications, medical equipment, and power electronics, the need for efficient and effective copper foil processing methods has become more important than ever before.

Copper foil processing plays a critical role in the performance of high-frequency transformers. It affects the transformer’s electrical conductivity, thermal stability, and mechanical strength, which are essential for ensuring the transformer’s overall efficiency and reliability. Furthermore, the quality of copper foil used in transformer design and production directly impacts the transformer’s operating frequency, power handling capacity, and noise level.

What is copper foil, and why is it important in high-frequency transformer design and application?

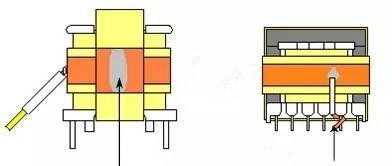

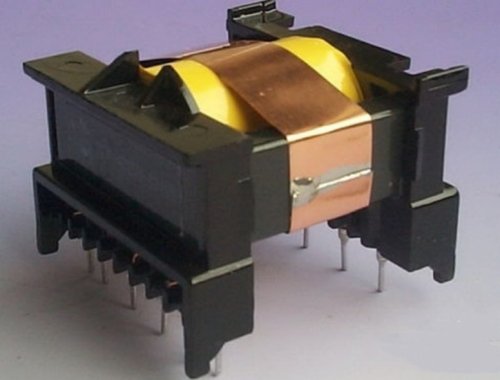

Copper foil is a thin sheet of copper metal that is widely used in high-frequency transformer design and application. It is an essential component of transformer winding, which is responsible for transferring energy from the primary to the secondary circuit. Copper foil is preferred over other conductive materials because of its excellent electrical conductivity, thermal stability, and mechanical strength. These properties are particularly important in high-frequency transformers, where efficiency and reliability are critical.

In high-frequency transformer design, the copper foil’s thickness, width, and surface roughness must be carefully controlled to optimize the transformer’s performance. The thickness of the copper foil determines the transformer’s power handling capacity, while the width and surface roughness affect the transformer’s operating frequency and noise level.

Copper foil processing plays a crucial role in high-frequency transformer design and application. Various techniques, such as etching, electroplating, laser cutting, and chemical milling, are used to fabricate copper foil with specific properties tailored to the transformer’s requirements. The choice of copper foil processing technique depends on factors such as the required thickness, surface roughness, and width, as well as the desired production efficiency and cost.

What are the different methods of copper foil processing?

There are several methods of copper foil processing that are used in high-frequency transformer design and production. Each method has its advantages and disadvantages, and the choice of method depends on the specific requirements of the transformer being designed. Here are some of the most common methods of copper foil processing:

- Etching: Etching is a process that uses chemicals to remove unwanted portions of the copper foil. A photoresist is applied to the copper foil, and a mask is placed over the photoresist. The mask is then exposed to light, which hardens the photoresist in the areas that are not covered by the mask. The unhardened photoresist is then removed using a developing solution, leaving behind the areas of copper foil that were exposed. The exposed copper is then etched away using an etching solution, leaving behind the desired pattern.

- Electroplating: Electroplating is a process that involves depositing a layer of metal onto the surface of the copper foil. The copper foil is first cleaned and then immersed in an electrolyte solution containing metal ions. A current is applied to the solution, causing the metal ions to deposit onto the surface of the copper foil. The thickness of the deposited metal layer can be controlled by adjusting the current and the immersion time.

- Laser cutting: Laser cutting is a process that uses a laser beam to cut through the copper foil. The laser beam is focused onto the surface of the copper foil, vaporizing the metal and creating a cut. Laser cutting is precise and can produce complex shapes and patterns, but it can also be slow and expensive.

- Chemical milling: Chemical milling is a process that involves selectively etching the copper foil using a chemical solution. The solution is applied to the copper foil using a mask, which protects the areas of the foil that should not be etched. The solution is then washed away, leaving behind the desired pattern.

Can copper foil be processed manually, or does it require specialized machinery?

Copper foil can be processed manually or with specialized machinery, depending on the processing technique and the requirements of the transformer being designed.

Manual processing techniques, such as hand cutting and etching, can be used for small-scale production and prototyping. These techniques are relatively simple and require only basic tools and equipment, such as scissors, scalpels, and chemical etching solutions. However, manual processing can be time-consuming and imprecise, making it unsuitable for large-scale production or for designs that require a high degree of accuracy.

How does the thickness of the copper foil affect its processing and performance in high-frequency transformers?

The thickness of the copper foil in high-frequency transformers can affect both its processing and performance in several ways:

- Processing: Thicker copper foils can be more challenging to process due to their increased stiffness and reduced flexibility. This can make it more difficult to wind the foil around the transformer core, which can increase the risk of defects and reduce the efficiency of the transformer.

- Skin Effect: At high frequencies, electrical current tends to flow on the surface of the conductor. This is known as the skin effect. A thicker copper foil will have a larger skin depth, meaning that more of the current will be confined to the surface. This can increase the resistance of the copper foil, which can reduce the efficiency of the transformer.

- Eddy Currents: Eddy currents are electrical currents that circulate within a conductor in response to a changing magnetic field. Thicker copper foils can be more prone to eddy currents due to their larger cross-sectional area. Eddy currents can lead to increased heating and power losses, which can reduce the efficiency of the transformer.

- Magnetic Flux: The thickness of the copper foil can also affect the magnetic flux density in the transformer core. Thicker copper foils can reduce the magnetic flux density, which can decrease the efficiency of the transformer. However, thicker copper foils can also increase the magnetic coupling between the windings, which can improve the performance of the transformer.

Overall, the optimal thickness of the copper foil will depend on the specific requirements of the transformer and the frequency of operation. Thinner copper foils may be more suitable for high-frequency applications where skin effect and eddy currents are a concern, while thicker copper foils may be more suitable for low-frequency applications where magnetic flux density and magnetic coupling are more important.

What are the most common mistakes to avoid when processing copper foil for high-frequency transformers?

The thickness of copper foil is an important factor that affects both the processing and performance of high-frequency transformers. Here’s how:

- Processing: The thickness of the copper foil affects the processing technique that can be used. Thicker foils may require more specialized processing equipment, such as laser cutters or chemical milling machines, to achieve the desired pattern or shape. Thin foils may be more easily processed using manual techniques or simple etching methods. The choice of processing technique can also affect the final performance of the transformer.

- Performance: The thickness of the copper foil affects the transformer’s power handling capacity and operating frequency. Thicker foils have a higher current carrying capacity and can handle more power, but they may also increase the transformer’s resistance and reduce its efficiency. Thinner foils have a lower current carrying capacity but may increase the transformer’s operating frequency and reduce noise levels. Therefore, the thickness of the copper foil must be carefully selected to optimize the transformer’s performance.

In general, the thickness of the copper foil is typically in the range of 5 to 35 micrometers for high-frequency transformers. The specific thickness chosen depends on the transformer’s requirements, such as its power handling capacity, operating frequency, and efficiency. Designers must carefully consider the trade-offs between the thickness of the copper foil, processing techniques, and the transformer’s performance to achieve the desired results.

What are some tips for achieving high precision and accuracy when processing copper foil?

Achieving high precision and accuracy when processing copper foil is critical for designing high-performance transformers. Here are some tips for achieving the best results:

- Use high-quality copper foil: Start with high-quality copper foil that is free of defects or impurities. Copper foil with a smooth surface and a uniform thickness will produce more consistent results during processing.

- Choose the right processing method: Select the processing method that is most suitable for the transformer design and specifications. Laser cutting and chemical milling are typically the most accurate methods for producing complex shapes and patterns.

- Use high-resolution designs: Use high-resolution design files and templates to ensure accurate reproduction of the desired pattern. Avoid low-resolution images or templates, as they may produce inaccurate results.

- Check the tooling regularly: Regularly inspect the tools and equipment used for processing copper foil to ensure they are functioning correctly. Dull blades or worn-out tools can produce inaccurate cuts and lead to poor performance.

- Monitor the process parameters: Monitor the process parameters, such as temperature, pressure, and exposure time, to ensure consistent results during processing. Variations in these parameters can result in poor quality or inconsistent results.

- Test and measure the results: Test and measure the processed copper foil to ensure it meets the desired specifications. Use precision measurement tools, such as micrometers or laser scanners, to verify accuracy and precision.

In conclusion, copper foil processing plays a crucial role in the design and application of high-frequency transformers. There are various methods of copper foil processing available, including hand cutting, chemical etching, laser cutting, electroplating, and chemical milling. Each of these techniques has its advantages and disadvantages, depending on the requirements of the transformer design and the desired specifications. For instance, manual processing methods are suitable for small-scale production and prototyping, while specialized machinery is necessary for large-scale production and designs that require high precision and accuracy.

Regardless of the processing technique used, achieving excellent precision and accuracy when processing copper foil is essential for designing high-performance transformers. Designers must carefully select the thickness of the copper foil, choose the right processing method, use high-resolution designs, check the tooling regularly, monitor the process parameters, and test and measure the results to ensure that the processed copper foil meets the desired specifications.