High frequency transformer cores serve as the backbone of transformer operation, playing a crucial role in the efficient conversion and transfer of electrical energy. These cores, often constructed from magnetic materials, create a closed magnetic circuit that facilitates the desired power transformation. By controlling the magnetic flux and minimizing energy losses, high frequency transformer cores ensure the reliable functioning of various electronic devices, power supplies, and distribution systems. Understanding the significance of these cores is fundamental to optimizing transformer performance.

In this blog, we delve into the fascinating world of high frequency transformer cores and their impact on transformer operation. Specifically, we focus on the influence of core shape on the overall functionality and performance of these essential components. The shape of the core, be it E-core, U-core, or toroidal, goes beyond aesthetics; it directly affects critical aspects such as magnetic flux distribution, power losses, and electromagnetic interference. By exploring how different core shapes impact these factors, we can unravel the secrets to enhancing transformer efficiency, minimizing losses, and ensuring stable power transfer.

What is the role of the core in a high frequency transformer?

The core in a high frequency transformer plays a crucial role in facilitating the efficient transfer of electrical energy between circuits. Its primary function is to provide a closed magnetic pathway for the magnetic flux generated by the transformer’s primary winding. The core material is chosen for its high magnetic permeability, allowing it to concentrate the magnetic field and minimize losses.

The core serves 4 important purposes:

- Magnetic Flux Conduction: The core’s magnetic properties enable it to channel and direct the magnetic flux generated by the primary winding. It helps create a closed loop for the magnetic field, which is essential for efficient energy transfer.

- Magnetic Field Concentration: By concentrating the magnetic field within the core, the core increases the coupling between the primary and secondary windings. This coupling allows for effective energy transfer from the primary to the secondary circuit.

- Reducing Energy Losses: The core material is selected for its low magnetic hysteresis and eddy current losses, minimizing energy losses during the energy conversion process. This ensures that a significant portion of the electrical energy is efficiently transferred from the primary to the secondary winding.

- Controlling Inductance: The core’s shape and material influence the inductance of the transformer. By selecting the appropriate core shape and material, engineers can control the inductance to match the desired performance characteristics of the transformer.

How does the shape of the core affect the performance of the transformer?

The shape of the core in a high frequency transformer has a significant impact on its performance. Here are 6 ways in which the core shape affects the transformer:

1.Magnetic Flux Distribution:

The shape of the core determines how the magnetic flux is distributed within the transformer. An efficient core shape ensures a uniform distribution of magnetic flux, minimizing magnetic leakage and maximizing the coupling between the primary and secondary windings. This leads to efficient energy transfer and improved overall performance.

2.Power Losses:

The core shape influences the power losses within the transformer. In high frequency transformers, two primary types of losses occur: hysteresis losses and eddy current losses. The core shape can affect the magnitude and distribution of these losses. By choosing an appropriate core shape, engineers can minimize these losses and improve the transformer’s efficiency.

3.Size and Weight:

The shape of the core can impact the size and weight of the transformer. Different core shapes have varying levels of material utilization and winding arrangements, which can affect the overall dimensions of the transformer. By selecting an optimal core shape, engineers can design transformers that are compact, lightweight, and suitable for specific space constraints or applications.

4.Electromagnetic Interference (EMI):

The core shape can also impact electromagnetic interference (EMI) within the transformer. Certain core shapes can help reduce the radiated electromagnetic fields and minimize EMI, making the transformer more compatible with surrounding electronic devices and systems.

5.Frequency Response:

The core shape plays a role in determining the transformer’s frequency response. Different core shapes have different magnetic characteristics, including inductance, saturation levels, and frequency limits. The choice of core shape should align with the intended frequency range of the transformer to ensure optimal performance within that range.

6.Manufacturing Considerations:

The shape of the core can influence the ease and cost of manufacturing the transformer. Certain core shapes may require specific tooling or winding techniques, affecting the manufacturing process. By considering the manufacturability of different core shapes, engineers can optimize production efficiency and cost-effectiveness.

What are the different core shapes commonly used in high frequency transformers?

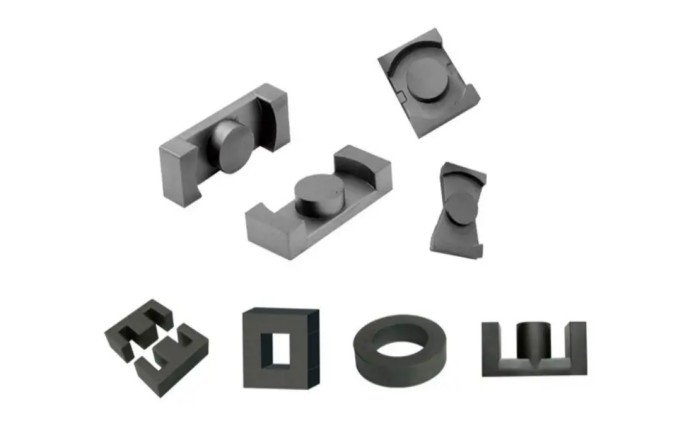

Below 6 core shapes commonly used in high frequency transformers. The choice of core shape depends on various factors such as the application, power requirements, space constraints, and desired performance characteristics. Here are some of the most common core shapes used in high frequency transformers:

1.E-Core:

The E-core shape resembles the letter “E” when viewed from the side. It consists of a central leg with two outer legs, forming a closed magnetic path. E-core transformers are widely used due to their simplicity, compactness, and ease of manufacturing. They are suitable for applications with moderate power requirements.

2.U-Core:

The U-core shape resembles the letter “U” when viewed from the side. It consists of two parallel legs connected by a horizontal crossbar. U-core transformers provide better magnetic flux coupling compared to E-core transformers due to their increased cross-sectional area. They are often used in higher power applications and where lower power losses are desired.

3.Toroidal Core:

The toroidal core shape is donut-shaped with a hollow center. The winding wire passes through the center, encircling the entire core. Toroidal transformers offer several advantages, including high efficiency, low electromagnetic radiation, and reduced size and weight. They are commonly used in power supplies, audio equipment, and other applications where compactness and low EMI are essential.

4.E-I Core:

The E-I core combines the E-core and I-core shapes. It consists of two E-shaped halves placed back-to-back, forming an “E-I” configuration. This core shape provides a larger surface area for winding and improved magnetic coupling compared to the E-core. E-I core transformers are often used in applications requiring higher power handling and lower power losses.

5.Pot Core:

The pot core shape consists of a cylindrical core with a central winding window. The winding is typically placed around a bobbin that fits within the central window. Pot core transformers offer high magnetic flux density, low leakage inductance, and excellent shielding properties. They are commonly used in power supplies and high-frequency applications.

6.RM Core:

The RM core shape features a rectangular cross-section with rounded edges. It provides a compact design with excellent winding capabilities. RM core transformers are widely used in consumer electronics, telecommunications, and other applications requiring efficient power transfer and compact size.

These are just 6 examples of the core shapes used in high frequency transformers. Each shape offers specific advantages and is selected based on the specific requirements of the application. Engineers consider factors such as power handling, efficiency, size constraints, and frequency response when choosing the appropriate core shape for a given high frequency transformer.

Which core shape is the most efficient for high frequency transformer operation?

The efficiency of a high frequency transformer depends on various factors, including the core shape. However, there is no one-size-fits-all answer to which core shape is the most efficient for all high frequency transformer applications. The optimal core shape depends on the specific requirements and constraints of the application.

Different core shapes have their advantages and disadvantages in terms of efficiency. For example:

- Toroidal cores: Toroidal cores are known for their high efficiency due to the uniform magnetic flux distribution and reduced winding lengths. They offer low magnetic leakage and reduced winding losses. Toroidal transformers are commonly used in applications where efficiency is a critical factor, such as power supplies and audio equipment.

- U-cores and E-I cores: These core shapes provide larger surface areas for winding and better magnetic coupling compared to E-cores. As a result, U-cores and E-I cores can offer improved efficiency in high power applications where minimizing power losses is crucial.

- Pot cores: Pot cores provide high magnetic flux density and low leakage inductance. These characteristics can contribute to higher efficiency in certain applications, especially at higher frequencies.

However, it’s important to note that efficiency is not solely determined by the core shape. Other factors such as core material, winding technique, magnetic circuit design, and overall transformer construction also play significant roles in determining efficiency.

To determine the most efficient core shape for a specific high frequency transformer application, engineers need to consider various factors, including power requirements, frequency range, space constraints, desired losses, and manufacturing considerations. By carefully evaluating these factors and conducting thorough design analysis, engineers can select the core shape that offers the best balance of efficiency, performance, and other requirements for the given application.

How does core shape impact the mgnetic flux distribution in the transformer?

The shape of the core in a transformer has a significant impact on the distribution of magnetic flux within the transformer. The magnetic flux distribution determines the efficiency of energy transfer and the overall performance of the transformer. Here’s how core shape influences magnetic flux distribution:

1.Magnetic Path Length:

The core shape affects the length of the magnetic path within the transformer. A shorter and more direct magnetic path reduces magnetic resistance and enhances magnetic flux flow. This leads to improved coupling between the primary and secondary windings, resulting in efficient energy transfer. Different core shapes offer varying magnetic path lengths, impacting the flux distribution accordingly.

2.Leakage Flux:

Core shape also influences the occurrence of leakage flux, which refers to the portion of the magnetic flux that does not link with the windings. Leakage flux can result in energy losses and reduced transformer efficiency. By selecting an appropriate core shape, engineers can minimize leakage flux and enhance the coupling of magnetic flux with the windings, improving the overall performance of the transformer.

3.Magnetic Saturation:

The core shape affects the saturation characteristics of the transformer. Saturation occurs when the magnetic field strength reaches the maximum limit that the core material can handle. Different core shapes have varying magnetic cross-sectional areas, which can affect the saturation behavior of the core. The core shape should be chosen carefully to prevent excessive magnetic saturation, which can lead to reduced efficiency and increased losses.

4.Flux Concentration:

The shape of the core determines how the magnetic flux is concentrated within the transformer. A well-designed core shape ensures the maximum utilization of the core material, concentrating the magnetic flux within the core and minimizing losses. Efficient flux concentration leads to improved energy transfer and reduced magnetic losses.

5.Magnetic Shielding:

Certain core shapes offer better magnetic shielding properties. They help contain the magnetic flux within the core and reduce its impact on surrounding components or circuits. This is particularly important in applications where minimizing electromagnetic interference (EMI) is essential.

What are the advantages and disadvantages of different core shapes?

| Core Shape | Advantages | Disadvantages |

| E-Core | Simple and cost-effective manufacturing Compact size and space-efficient | Higher magnetic leakage Limited power handling capacity |

| U-Core | Suitable for low tomoderate power applications Better magnetic flux coupling Improved powerhandling capacity- Reduced magnetic leakage | Potential for higher core losses More complex manufacturing process Larger size compared to some other core shapes Potential for higher core losses |

| Toroidal | suitable for moderate to high power applications Excellent magneticflux coupling High efficiency anduniform magnetic path Compact size and weight | More challenging manufacturing process Limitations in very high-power applications |

| E-I Core | Low electromagnetic interference (EMI) Larger winding -surface area and improved coupling Suitable for higher power applications Better power handling capacity | More complex construction andmanufacturing process Larger size compared to some othercore shapes Potential for increased magnetic leakage |

| Pot Core | Reduced core losses compared to E-Core High magnetic flux density and low leakage inductance Excellent shielding properties Compact size and weight | More challenging manufacturing process Limitations in very high-power applications |

Can the choice of core shape affect the size and weight of the transformer?

Yes, the choice of core shape can significantly impact the size and weight of a transformer. Different core shapes have varying levels of material utilization and winding arrangements, which directly affect the overall dimensions and weight of the transformer.

Here’s how the core shape influences the size and weight:

- Material Utilization: The core shape determines how efficiently the core material is utilized within the transformer. Certain core shapes, such as toroidal cores, provide a higher utilization of the core material due to their continuous and uniform winding path. This leads to more compact transformers with reduced size and weight compared to other core shapes that may have less efficient material utilization.

- Winding Arrangement: The shape of the core also affects the arrangement and configuration of the windings. Different core shapes may allow for different winding techniques and arrangements, which can impact the size and weight of the transformer. Core shapes that facilitate shorter winding paths and tighter winding arrangements can result in more compact transformers.

- Magnetic Flux Distribution: The core shape influences the distribution of magnetic flux within the transformer. Efficient core shapes with optimized flux paths can result in compact transformers by minimizing the need for excess core material. This can help reduce both the size and weight of the transformer.

- Power Handling Capability: The choice of core shape is closely related to the power handling capacity of the transformer. Different core shapes have varying power handling capabilities, and the selection of an appropriate core shape depends on the desired power requirements. By choosing a core shape that matches the power needs, the size and weight of the transformer can be optimized.

Does the core shape have any influence on electromagnetic interference (EMI)?

Yes, the core shape of a transformer can have an influence on electromagnetic interference (EMI). EMI refers to the electromagnetic radiation or noise generated by electronic devices, which can interfere with the proper operation of other nearby devices or systems.

Here’s how the core shape can impact EMI:

- Magnetic Field Containment: Certain core shapes, such as toroidal cores or pot cores, have a closed magnetic path that helps contain the magnetic field within the core itself. This can reduce the emission of electromagnetic radiation outside the transformer, minimizing EMI. The closed-loop nature of these core shapes provides better magnetic field confinement compared to open core shapes like E-cores.

- Flux Leakage: Core shape also affects the amount of flux leakage that occurs in a transformer. Flux leakage refers to the portion of magnetic flux that does not link with the windings and escapes from the core. Excessive flux leakage can result in increased EMI. Core shapes that allow for tighter magnetic coupling between the windings and minimize leakage flux can help reduce EMI.

- Shielding: Some core shapes, such as pot cores or shielded cores, incorporate built-in magnetic shielding materials or structures. These shielding elements help attenuate the electromagnetic radiation emitted from the transformer, reducing its impact on nearby circuits or systems. The shielding properties of the core shape can contribute to lower EMI levels.

- Frequency Response: Different core shapes can have varying effects on the frequency response of a transformer. The core shape influences factors such as parasitic capacitance and inductance, which can affect the impedance characteristics and resonance behavior of the transformer. By selecting a core shape that minimizes resonances and optimizes frequency response, the potential for EMI generation can be reduced.

How does core shape impact the overall efficiency and power losses of the transformer?

The core shape of a transformer can have a significant impact on its overall efficiency and power losses.

Here’s how the core shape influences efficiency and power losses:

- Magnetic Flux Distribution: The core shape affects how the magnetic flux is distributed within the transformer. A well-designed core shape ensures efficient flux concentration and minimizes magnetic leakage. When the magnetic flux is properly concentrated within the core and effectively links with the windings, it results in higher efficiency and reduced power losses.

- Core Material Utilization: Different core shapes utilize core materials differently. Some core shapes, such as toroidal cores or pot cores, provide a more uniform and continuous magnetic path, maximizing the utilization of the core material. This efficient material utilization reduces core losses and improves overall efficiency.

- Core Losses: Core losses primarily include hysteresis loss and eddy current loss. The core shape influences the magnitude of these losses. Core shapes that minimize the magnetic path length, promote uniform flux distribution, and reduce flux density variations can help minimize hysteresis and eddy current losses, resulting in higher efficiency.

- Winding Length: The core shape also affects the length of the windings in relation to the magnetic path length. Shorter winding lengths reduce resistance and copper losses. Certain core shapes, like toroidal cores, offer shorter winding lengths compared to other core shapes, leading to lower power losses.

- Saturation Behavior: The core shape influences the saturation characteristics of the transformer. Saturation occurs when the core material reaches its maximum magnetic flux density. Different core shapes have varying cross-sectional areas and saturation behaviors. By selecting an appropriate core shape, engineers can optimize the magnetic flux density and prevent excessive saturation, which can result in reduced efficiency and increased power losses.

Are there any specific design considerations when selecting a core shape for a high frequency transformer?

Yes, there are specific design considerations to keep in mind when selecting a core shape for a high frequency transformer. These considerations help ensure optimal performance and efficiency. Here are 7 key factors to consider:

1.Frequency Response:

The core shape should be chosen based on the desired frequency range of operation. Different core shapes have different frequency responses due to factors such as parasitic capacitance and inductance. It’s important to select a core shape that provides a frequency response suitable for the application’s requirements and minimizes any resonance effects.

2.Power Handling Capacity:

Consider the power handling capability required for the transformer. Some core shapes are better suited for low power applications, while others can handle higher power levels. The selected core shape should have the appropriate size, winding arrangements, and magnetic properties to handle the expected power without exceeding temperature limits or causing excessive losses.

3.Efficiency and Power Losses:

Evaluate the core shape’s impact on the overall efficiency and power losses of the transformer. Different core shapes can have varying levels of core losses, such as hysteresis and eddy current losses. Look for a core shape that minimizes these losses and maximizes efficiency to achieve the desired performance.

4.Magnetic Flux Distribution:

Consider how the core shape affects the magnetic flux distribution within the transformer. The core shape should facilitate efficient flux concentration and minimize leakage flux. This ensures maximum coupling with the windings and reduces losses. An optimized flux distribution leads to improved energy transfer and performance.

5.Size and Weight Constraints:

Take into account the size and weight restrictions of the application. Some core shapes, like toroidal or pot cores, offer more compact designs and better material utilization, resulting in smaller and lighter transformers. Consider the available space and weight limitations when selecting the core shape.

6.EMI Considerations:

Assess the core shape’s impact on electromagnetic interference (EMI). Certain core shapes, such as toroidal or pot cores, provide better magnetic field containment and reduced EMI emissions. If EMI mitigation is critical for the application, choose a core shape that offers good shielding properties and minimizes radiated electromagnetic fields.

7.Manufacturing Feasibility:

Evaluate the feasibility of manufacturing the selected core shape. Some core shapes may be more complex to manufacture or require specialized techniques, which can impact production costs and lead times. Consider the availability of the chosen core shape and ensure it aligns with the manufacturing capabilities and resources.

Selec the right core shape is of paramount importance for achieving optimal transformer performance. Engineers and designers must carefully consider the specific requirements of their applications and choose a core shape that aligns with those needs. This entails a comprehensive understanding of core materials, losses, operating frequencies, and power levels.

We must encourage further research and exploration in the field of high frequency transformer core design. As technology evolves and new demands emerge, there is a continuous need for advancements in core materials, geometries, and manufacturing techniques. Researchers and industry professionals should collaborate to develop innovative solutions that address the challenges posed by high frequency operation, power density, and thermal management.