Have you ever faced the frustrating problem of having a transformer that just won’t fit inside your mechanical equipment? I’ve been there, and it’s a common challenge that many engineers and technicians run into. Transformers, especially those designed for high power or specialized functions, often come in sizes that exceed the space available causing headaches related to tight spaces, inadequate ventilation, and even increased costs.

Not only can the physical size restrict proper installation, but oversized transformers can also lead to heat dissipation problems and hefty expenses that could have been avoided with better planning. This problem can quickly spiral, affecting equipment performance and maintenance.

In this blog, I want to share practical solutions and key considerations I’ve learned about dealing with oversized transformers. Whether you need to customize the transformer design, rethink installation strategies, or modify your equipment layout, you’ll find actionable insights here to help you overcome the size barrier effectively.

1.Understanding Transformer Size and Its Impact

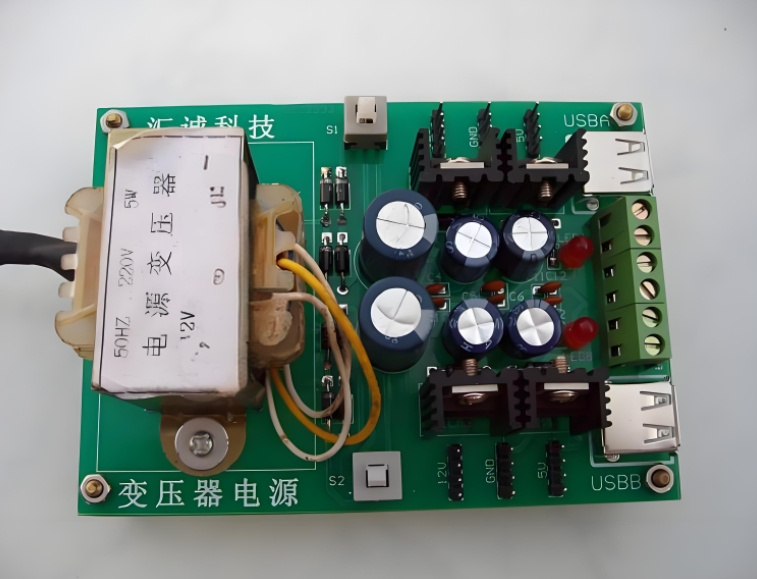

Transformer size is directly related to its power rating, typically measured in volt-amperes (VA), kilovolt-amperes (kVA), or megavolt-amperes (MVA). The power rating indicates the maximum load the transformer can safely handle. As the power rating increases, the physical dimensions of the transformer generally grow because more copper windings, larger cores, and robust insulation are required to accommodate higher current and voltage levels. Proper sizing ensures the transformer operates efficiently, minimizing energy losses during voltage conversion and preventing excessive heat build-up.

Oversized transformers, while seemingly providing extra capacity, cause several problems. They increase initial costs due to more materials and manufacturing complexity. Larger size also complicates installation, especially in mechanical equipment with limited space. Furthermore, oversized transformers tend to operate under low load conditions, leading to poor efficiency and increased reactive power losses. Heat dissipation becomes challenging, potentially reducing the transformer’s lifespan and reliability.

Therefore, proper sizing is crucial when space constraints exist in mechanical equipment. Selecting a transformer that matches the actual load requirements and fits the installation environment helps optimize performance, reduce costs, and simplify installation.

2.Evaluate the Transformer’s Appropriateness

Evaluating a transformer’s appropriateness is a critical step to ensure efficient and safe operation within mechanical equipment. First, assess whether the transformer’s power rating accurately matches the electrical load and application requirements. Oversized transformers can lead to inefficiency and added costs, while undersized units risk overheating and premature failure. Carefully calculate the expected load, including future expansions or peak demands, and confirm the transformer’s rating accommodates these factors without excessive margin.

If the transformer appears too large for the available space or operation, consider downsizing to a model with a more suitable rating that still meets the load demands effectively. Alternatively, explore different transformer types: dry-type transformers are often more compact and safer for indoor use but may have lower cooling capacity, whereas liquid-filled transformers typically handle higher loads and offer better cooling but require additional safety and environmental considerations.

Always factor in site and equipment constraints such as physical space limitations, ventilation quality, and safety regulations. Proper ventilation is crucial to manage heat dissipation, and equipment layout must allow safe access for maintenance. Ensuring these conditions align with your transformer choice is essential for optimal integration and longevity.

3.Customization and Design Solutions

When facing space constraints, customization and design solutions become essential to ensure transformers fit seamlessly within mechanical equipment. One effective approach is to explore custom transformer enclosures tailored specifically for limited spaces. These enclosures can be designed from durable, lightweight materials that also provide waterproofing and EMI shielding, aligning with my experience in crafting efficient and noise-reduced transformer solutions. Custom enclosures not only protect the transformer but also optimize its footprint to maximize available space.

Collaborating closely with manufacturers is another key step. By working together to optimize the transformer’s external dimensions and internal coil and winding layouts, it’s possible to create compact designs without sacrificing efficiency or safety. Manufacturers can also apply advanced materials and thermal management techniques to maintain performance within tighter spatial limits.

Additionally, adapting wiring configurations and strategically placing terminals can significantly reduce installation space requirements. Customized terminal blocks, optimized input/output layouts, and streamlined wiring routes help minimize clutter and improve accessibility for maintenance. These adjustments contribute to a more compact and manageable transformer installation, especially in environments with stringent space and EMI control needs.

4.Alternative Installation Strategies

When transformer size becomes a challenge within mechanical equipment, alternative installation strategies can offer effective solutions. One practical approach is to use multiple smaller transformers instead of a single large unit. This not only helps fit within confined spaces but can also enhance system reliability by isolating loads and simplifying maintenance.

Another option is to install transformers externally or remotely, away from the mechanical equipment. With proper wiring, shielding, and protection especially considering EMI concerns, which you often focus on in your designs,this setup preserves internal space while maintaining safe power delivery. External installation also allows for easier cooling and access for inspection and servicing.

Additionally, modular or split transformer designs provide flexible installation alternatives. Modular transformers can be assembled onsite to tailor capacity, while split transformers separate core and coil sections, enabling placement within tight or awkward spaces. These configurations can be engineered for waterproofing, noise reduction, and efficiency aligning well with your expertise and help overcome space restrictions without compromising performance or safety.

5.Professional Installation and Engineering Support

Consulting transformer installation experts is crucial when dealing with large or complex transformers, especially in space-constrained mechanical equipment. These professionals bring the necessary knowledge and experience to ensure that the installation complies with safety standards, electrical codes, and operational requirements. Their guidance helps avoid costly mistakes and guarantees the transformer performs reliably over its lifespan.

For large transformers, specialized equipment and installation services become indispensable. Cranes, hydraulic lifts, and rigging tools designed specifically for heavy electrical equipment enable safe handling and precise positioning. Expert installers also manage challenges such as minimizing mechanical stress and protecting sensitive components from damage during movement and setup.

Thorough planning for transport, positioning, and commissioning is essential to streamline the entire process. This includes coordinating logistics to navigate access constraints, preparing foundations or support structures, and scheduling tests like insulation resistance and voltage ratio verification. Professional teams ensure every step is executed efficiently, reducing downtime and ensuring the transformer operates at peak performance from day one.

6.Upgrading or Modifying Installation Environment

When transformer size poses installation challenges, upgrading or modifying the installation environment can be an effective solution. First, consider altering your mechanical equipment layout or the installation site itself. By rearranging components or redesigning internal compartments, you can create the necessary space for the transformer without compromising other system functions. This may involve reconfiguring wiring paths or relocating auxiliary equipment.

If space remains tight, reinforcing foundations or expanding the installation area could be feasible. A stable, reinforced foundation is essential to support the added weight and vibration of larger transformers, ensuring long-term operational safety and reliability. Expanding the physical enclosure or room may require structural modifications but can significantly ease installation and maintenance.

Finally, as someone who focuses on designing waterproof transformers with efficiency and safety in mind, I emphasize proper grounding, ventilation, and cooling. Adequate ventilation and cooling systems prevent heat buildup that can degrade transformer performance and lifespan. Reliable grounding is critical for safety, reducing the risk of electrical faults and interference. These environmental upgrades ensure your transformer runs efficiently and safely within the modified installation space.

Conclusion:

When a transformer is too large to fit into your equipment, it’s not the end of the road—it’s a signal to reassess and adapt. In this blog, I’ve shared the main solutions I rely on: choosing more compact transformer types like toroidal or high-frequency designs, exploring custom options tailored to your specific space, and reviewing layout strategies with your engineering team.

In my experience, the key is finding the right balance getting the power you need without sacrificing fit, efficiency, or safety. Customization and expert guidance often make all the difference, especially when standard sizes just won’t work.

That’s why I always recommend planning early. By consulting with transformer specialists during your design phase, you can avoid costly adjustments later. If you’re ever unsure, don’t hesitate to reach out—I’m here to help you get it right the first time.