The power transformer converts the voltage (current) of one AC voltage (current) into a different AC voltage (current) of the same frequency or of a different frequency. By supplying the primary winding with alternating current, an alternating magnetic flux is generated, which induces an alternating electromotive force in the secondary winding.Secondary induced electromotive force is proportional to the number of turns of the primary and secondary windings, thus voltage is proportional to turns. This device is to transmit electrical energy, so its capacity is the most important factor to consider. A rated capacity is a way of expressing power, which is a measurement of the transmitted power, expressed in kVA or MVA.

In specified conditions, the rated voltage is used to determine the rated current that does not exceed the temperature rise limit.Power transformers with amorphous alloy iron cores save more energy and have extremely low no-load loss values, which gives them their biggest advantage.

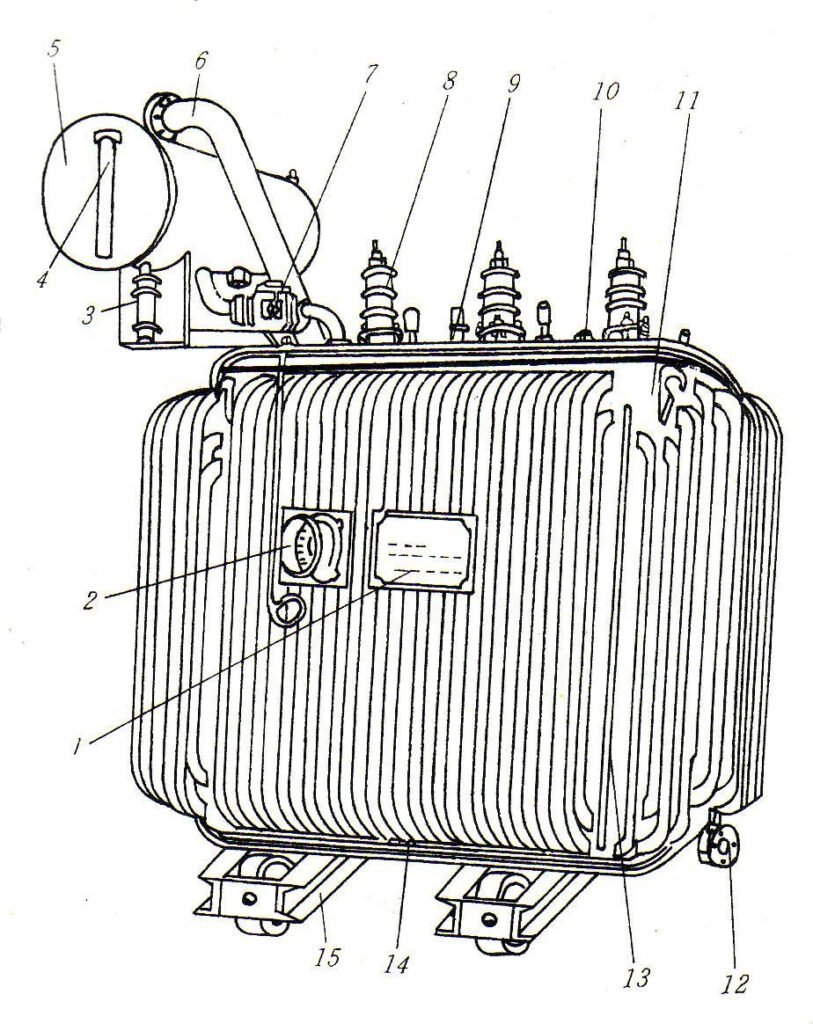

There are a number of basic characteristics of power transformers, which are as follows:

- The iron cores of power transformers make them extremely heavy and over sized.

- Iron core made of high-quality cold-rolled silicon steel sheet, shear burr less than 0.02 mm, full miter seam, no punching, no iron yoke. The core columns are stacked and double H glue is used to make the core three columns and two yokes a tight, flat and compact whole, thereby reducing the no-load loss, no-load current and noise.

- There can be one or more primary and secondary windings on them.

- Transformer coils are made of oxygen-free copper, which reduces copper loss, pad rounding, uniform electric field, and improved reliability. The inner winding support is strengthened to prevent deformation.

- The winding may be tapped like that of an autotransformer.

- Their laminated cores reduce eddy current losses.

- A power transformer should only be used in the low frequency band, not in the high frequency band, as using it in the high frequency band will result in excessive losses.

- In order to minimize series resistance, thick conductors are wrapped around them.

- Their construction is carefully selected to enable them to withstand the voltage applied to them.

- Power transformers are designed to prevent overheating caused by heat loss from the core and windings.

- Plate clamps and side beams provide a solid frame structure, and six-sided rigid positioning ensures that the body withstands the impact of various transportation conditions without dislocating.

- Path of the flux should be as short as possible to reduce leakage flux and minimize the energy required.

- Power transformers operate at high currents.

- Power transformers can have shell-type or core-type cores. Shell-type transformers have both primary and secondary windings placed on the center support, while core-type transformers have separate delay lines for the core windings.