In the world of industrial automation, precision and reliability are essential. I have worked with many automation systems, and one thing is clear. If the power supply is not stable and efficient, the entire system is at risk. Poor power management often causes overheating, equipment failure, and costly production delays.

Many systems still rely on traditional transformers that are bulky, less efficient, and prone to energy loss. Over time, these issues reduce overall system performance and increase maintenance demands.

This is where toroidal transformers make a real difference. Their compact design, efficient energy transfer, and minimal noise make them highly effective for industrial use. In this blog, I will explore how toroidal transformers help improve energy efficiency, enhance reliability, and support smoother operations in industrial automation systems.

What Are Toroidal Transformers?

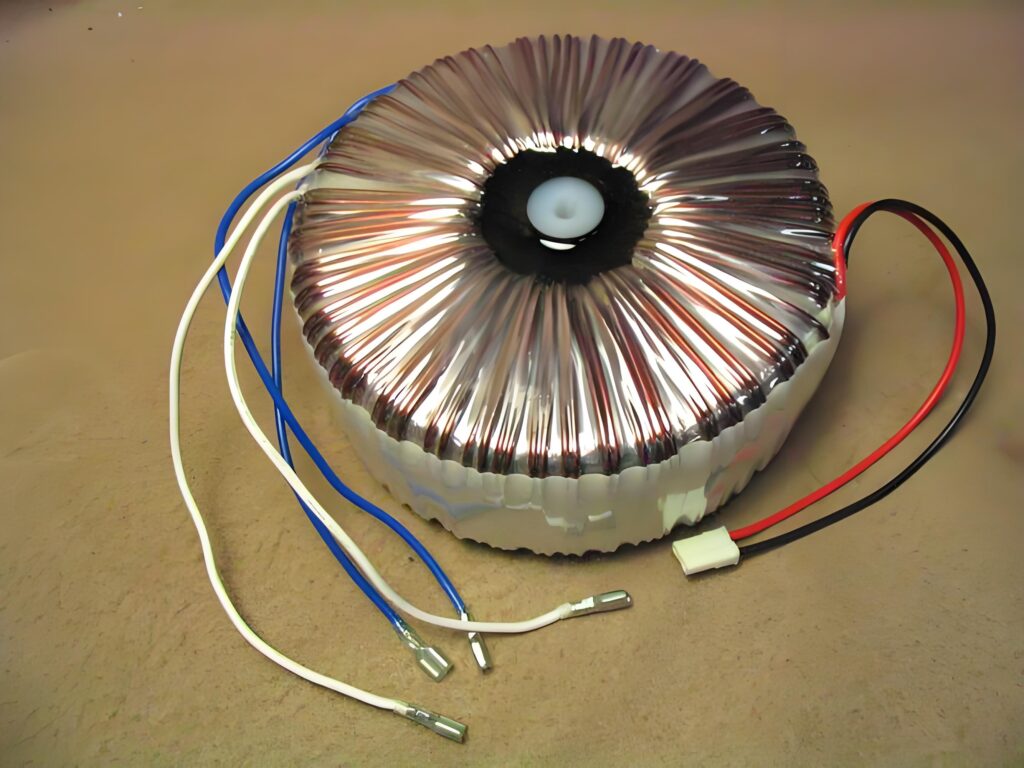

Toroidal transformers are a type of electrical transformer that uses a ring-shaped core made typically from iron or ferrite. The copper wire is wound around this doughnut-shaped core, creating a compact and highly efficient design. I often describe them as the smarter, space-saving alternative to traditional rectangular transformers.

What makes toroidal transformers stand out is their ability to minimize electromagnetic interference, reduce power loss, and operate quietly. Because of their shape, the magnetic field stays tightly contained within the core, which improves performance and safety especially in sensitive applications like industrial automation, medical devices, and precision instruments.

In my experience, toroidal transformers are a go-to choice when efficiency, reliability, and space-saving design are priorities. Whether you’re powering control systems, motor drives, or industrial sensors, this type of transformer offers a powerful combination of performance and practicality.

Toroidal Transformers Efficiency Advantages

When I consider how to boost the performance and reliability of industrial automation systems, toroidal transformers always stand out to me. Their unique design brings several efficiency advantages that not only streamline operations but also ensure long-term stability across various applications. Let me walk you through what makes them such a smart choice.

1.High Efficiency

Efficiency Levels: Toroidal transformers are known for their high efficiency, often reaching 95% to 99% due to their optimized design.

Magnetic Flux Concentration: The toroidal core ensures that magnetic flux remains concentrated, minimizing leakage flux and enhancing coupling between primary and secondary windings.

2.Compact and Lightweight Design

Space Efficiency: They are smaller and lighter than standard transformers, making them ideal for applications where space is limited.

Material Efficiency: The compact design results in less material usage, which can reduce overall costs.

3.Low Energy Losses

Off-Load Losses: Toroidal transformers have lower off-load losses, consuming significantly less power in standby mode compared to traditional transformers.

Heat Emission: They generally operate with lower heat emission, although they can retain heat longer due to their design.

4.Reduced Electromagnetic Interference (EMI)

Magnetic Field Containment: The toroidal design naturally shields magnetic fields, reducing EMI and making them suitable for sensitive electronic devices.

Noise Reduction: They produce less mechanical hum, which is beneficial in audio and medical applications.

5.Improved Reliability and Stability

Stable Power Supply: Toroidal transformers provide a stable power supply, which is crucial for maintaining consistent performance in critical systems.

Customization Options: They can be customized to meet specific application requirements, offering flexibility in design and performance.

How Toroidal Transformers Improve Efficiency

As someone deeply involved in industrial automation and transformer design, I’ve seen firsthand how toroidal transformers play a crucial role in improving system efficiency. Their unique design offers multiple performance advantages over traditional transformers. Let me walk you through some of the key ways toroidal transformers enhance efficiency in modern automation systems.

Toroidal transformers improve efficiency in below 5key ways:

1.Reduced Magnetic Flux Leakage

Efficiency Enhancement: The toroidal core design minimizes magnetic flux leakage, which significantly enhances efficiency compared to traditional transformers. This reduced leakage results in better magnetic coupling between the primary and secondary windings, leading to higher efficiency levels typically ranging from 90% to 95%.

2.Compact and Efficient Design

Space Efficiency: The compact design of toroidal transformers allows for a more efficient use of space. This compactness not only reduces the overall size and weight of the transformer but also minimizes the material needed for construction, which can lower production costs.

3.Lower Energy Losses

Heat Reduction: Toroidal transformers generally operate with lower heat generation due to reduced energy losses. This is beneficial as it extends the lifespan of both the transformer and the device it powers.

Off-Load Losses: They have lower off-load losses, meaning they consume less power when not under load, which is advantageous in applications where the transformer is frequently in standby mode.

4.Improved Magnetic Coupling

Efficient Power Transfer: The toroidal shape ensures that the magnetic flux remains concentrated within the core, enhancing magnetic coupling and leading to more efficient power transfer between the primary and secondary circuits.

5.Reduced Electromagnetic Interference (EMI)

Shielding Effect: The toroidal design naturally shields magnetic fields, reducing EMI and making these transformers suitable for applications requiring minimal interference, such as sensitive electronic equipment.

Toroidal Transformers Benefits for Industrial Automation Systems

From my hands-on experience, toroidal transformers are perfectly suited for modern industrial automation setups. Let me share four key reasons why they consistently stand out in practical use.

First is their space-saving design. Because of their compact and circular build, toroidal transformers fit easily into tight spaces like compact control panels. This helps me make the most of every inch in a cabinet and maintain a clean layout.

Second, they offer quiet operation, which is essential in sensitive environments. Whether I’m working with precise sensors or communication systems, the low noise and minimal vibration help keep interference to a minimum and ensure stable performance.

Third, they provide a long service life with reduced energy loss. The efficient magnetic flow in the toroidal core reduces heat buildup, which means the transformer and surrounding components last longer and require less maintenance.

Lastly, I appreciate their customizable specs. Whether I need single or dual input, different voltage outputs, or specific power levels, toroidal transformers can be tailored to meet the exact needs of the automation system I’m building.

These four features make toroidal transformers a smart, reliable choice for any industrial automation project.

Toroidal Transformers Applications in Real-World Automation

Toroidal transformers are widely used in various industrial automation applications due to their high efficiency, compact design, and low electromagnetic interference (EMI). Here are some real-world applications and case analyses:

Applications in Industrial Automation

1.Manufacturing Applications

In manufacturing environments, particularly in facilities using CNC machines and automated production lines, toroidal transformers significantly improve overall system efficiency through:

High Energy Efficiency:

Toroidal transformers typically achieve energy efficiency rates exceeding 95%, considerably higher than conventional EI transformers. This reduces energy loss and heat dissipation, allowing equipment such as CNC machinery and automated assembly lines to run cooler and more efficiently, minimizing downtime due to overheating issues.

Stable and Reliable Voltage Output:

Manufacturing processes demand precise and consistent voltage levels. Toroidal transformers provide minimal voltage fluctuations, resulting in fewer interruptions, improved operational consistency, and increased productivity by preventing unexpected downtime and product quality issues due to voltage instability.

Compact and Space-Saving Design:

Space is critical in manufacturing facilities. The compact size and lighter weight of toroidal transformers allow them to be efficiently integrated into tight spaces within machinery and control cabinets, optimizing the available workspace and facilitating easier maintenance and equipment upgrades.

2.Automation Systems

Toroidal transformers play a vital role in automation system control panels by delivering a robust and reliable power supply. Their benefits include:

Reduced Electromagnetic Interference (EMI):

Automation systems, particularly those with sensitive electronic controllers, are vulnerable to interference that may cause errors or system faults. Toroidal transformers, with their unique closed-loop construction, generate minimal EMI, resulting in clearer, interference-free signals and significantly improving system reliability and accuracy.

Improved System Stability and Uptime:

Automation systems are designed to run continuously, making voltage stability essential. Toroidal transformers ensure precise voltage regulation, thereby reducing unexpected shutdowns, equipment failures, and productivity losses due to unstable power conditions.

Lower Maintenance Requirements:

Due to their robust construction and higher reliability, toroidal transformers have a longer operational lifespan, significantly reducing maintenance needs. This not only cuts maintenance-related downtime but also decreases long-term operational costs, enhancing overall efficiency.

3.Robotics

Robotic systems demand compact, lightweight, efficient, and precise power solutions to ensure accuracy, agility, and reliability. Toroidal transformers meet these criteria, contributing to increased robotic efficiency through:

Compact Size and Lightweight Design:

Robotics require compact components due to limited internal space. Toroidal transformers’ smaller size and lower weight allow for reduced overall robot weight, increasing movement speed, agility, and operational flexibility.

Precision Power Delivery:

Robotic applications require highly precise motion control. The stable voltage supply provided by toroidal transformers ensures accuracy in robot movement, significantly reducing positioning errors and enhancing overall productivity and reliability.

Reduced Heat Generation and Energy Consumption:

Their high efficiency leads to lower heat output and reduced energy waste, which is crucial for continuous robotic operations. Lower heat generation also reduces the need for extensive cooling mechanisms, further lowering the operational costs and improving reliability in prolonged operations.

4.HVAC Systems

HVAC systems in industrial facilities must reliably provide stable heating, ventilation, and air conditioning. Toroidal transformers improve HVAC system efficiency through:

Energy Savings and Cost Efficiency:

HVAC systems typically run continuously, consuming significant energy. Toroidal transformers’ high energy efficiency substantially reduces energy consumption and operational costs. For instance, replacing conventional transformers with toroidal models can typically result in notable reductions in electricity usage.

Enhanced System Reliability and Stability:

By providing stable, regulated voltage and low harmonic distortion, toroidal transformers minimize risks to sensitive HVAC control equipment. This ensures fewer system malfunctions and operational disruptions, significantly improving system reliability and reducing maintenance frequency.

Lower Noise and Vibration Levels:

The unique design of toroidal transformers reduces mechanical vibrations and operational noise compared to traditional transformers. Lower operational noise contributes to a more comfortable working environment, which is particularly beneficial in industrial settings where noise control is essential.

Case Analysis: Industrial Automation Systems

Case Analysis 1: Industrial Automation Systems – Rockwell Automation Factory Systems

Background and Application Context:

Rockwell Automation is a leading provider of industrial automation and digital transformation solutions. Their factory automation systems require highly reliable, space-efficient, and EMI-minimizing power solutions. Custom-designed toroidal transformers have become critical components within their control systems, driving efficiency and stability in diverse factory environments.

Detailed Benefits and Technical Advantages:

Enhanced EMI Performance: Rockwell Automation’s custom toroidal transformers have an inherently closed-loop magnetic structure. This design significantly reduces electromagnetic interference (EMI), ensuring clear signal transmission and preventing disruption to sensitive industrial controllers, sensors, and communication equipment. Lower EMI enables more accurate process control, minimizes false alarms, and enhances overall factory productivity.

Optimized Thermal Management: The compact and circular construction of toroidal transformers provides superior thermal performance. Their high efficiency (typically above 95%) reduces heat dissipation significantly compared to traditional transformers. Within enclosed control cabinets, this results in less heat accumulation, improved reliability of electronic components, lower cooling costs, and extended equipment lifespan.

Flexible Voltage Taps for Multi-system Compatibility: Rockwell’s automation systems often integrate legacy systems with new technology. Toroidal transformers designed with multiple flexible voltage taps allow a single transformer to support diverse voltage levels seamlessly, providing greater flexibility in retrofitting older systems or integrating new equipment. This flexibility minimizes equipment redundancy, simplifies inventory management, and reduces downtime during upgrades.

Space-efficient Integration: Factory environments often have limited space available for control cabinets. Toroidal transformers’ compact size and lighter weight allow Rockwell Automation to optimize available space, enabling more sophisticated automation capabilities without enlarging the physical footprint of control cabinets. Thus, factories can scale automation solutions without additional infrastructure costs.

Case Analysis 2: Smart Grid Technology – ABB and Schneider Electric

Background and Application Context:

Smart grid technology demands precise, stable, and efficient power distribution, especially when integrating renewable energy sources like solar or wind. Companies such as ABB and Schneider Electric utilize custom-engineered toroidal transformers within their smart grid solutions, significantly enhancing grid efficiency and reliability.

Detailed Benefits and Technical Advantages:

High Energy Efficiency with Specialized Materials: ABB and Schneider Electric’s toroidal transformers are constructed using advanced magnetic core materials (such as amorphous or nanocrystalline alloys). These specialized materials dramatically reduce core losses, particularly during load cycling conditions commonly encountered in smart grid systems. The result is a substantial reduction in power wastage, optimizing energy efficiency throughout the grid and effectively facilitating renewable energy integration.

Reduced Power Loss during Load Cycling: Smart grid systems frequently experience fluctuating loads and power surges due to variable renewable energy sources. The custom toroidal transformers exhibit excellent performance under fluctuating loads, maintaining high efficiency even when grid conditions vary rapidly. Reduced power losses in these conditions translate directly into lower operational costs, improved reliability, and greater overall grid resilience.

Minimal Electromagnetic Interference: Smart grid infrastructure involves sensitive monitoring, metering, and communication equipment that is susceptible to EMI. Toroidal transformers’ low EMI characteristics ensure minimal interference with data communication signals, grid monitoring devices, and advanced metering infrastructure (AMI). This precision enhances real-time monitoring accuracy, ensuring reliable data acquisition and analysis for grid management.

Optimal Integration with Renewable Energy Systems: Toroidal transformers facilitate efficient and stable power conversion and distribution, which is critical for grid-tied renewable systems. Their precise voltage regulation and stability support consistent performance and power quality, enabling smart grids to seamlessly integrate renewable sources, maintain grid stability, and enhance environmental sustainability.

Toroidal Transformers Future Outlook

As someone who closely follows trends in industrial automation, I see toroidal transformers continuing to play a vital role in the future of smarter, more efficient systems.

Technological Developments

The demand for compact, energy-efficient, and low-noise solutions is only growing. With advancements in materials, winding techniques, and insulation systems, toroidal transformers are becoming even more reliable and adaptable. I expect to see improvements in power density, better thermal management, and increased integration with digital monitoring features. These upgrades will make toroidal transformers even more suitable for AI-driven automation, Industry 4.0 systems, and precision robotics.

Challenges and Opportunities

One challenge I often encounter is the need for even smaller and more efficient power components, especially in complex, space-limited control systems. While toroidal transformers already offer a compact form factor, future designs must keep pace with tighter requirements and rising energy standards.

However, this also presents a big opportunity. As more manufacturers move toward energy-saving designs and smarter automation, the demand for high-quality, customizable toroidal transformers will grow. For me and many others in the field, this opens up new possibilities to design systems that are not only more efficient but also more reliable and easier to maintain.

In my view, the future of toroidal transformers is bright, and they will remain a key building block in the next generation of industrial automation solutions.

Why Choose Unicreed Toroidal Transformers

Advantages of Unicreed Toroidal Transformers

- Quality and Certifications: Unicreed transformers are certified by CE, UL, RoHS, and more, ensuring compliance with global safety and performance standards. This certification guarantees that their products meet rigorous international standards, providing assurance of quality and reliability.

- Versatile Applications: Unicreed caters to a wide range of sectors, including industrial control systems, medical devices, renewable energy, and green lighting. Their transformers are used in diverse applications such as ships, trains, wind turbines, lifts, escalators, audio and lighting systems, solar panels, and household appliances.

- Rapid Customization: Unicreed offers rapid prototyping within 48 hours and samples in under two weeks. This fast turnaround time is crucial for businesses needing quick development and testing of custom transformer solutions.

- Risk-Free Testing: Unicreed provides free samples to ensure customer satisfaction. This allows potential clients to test the quality and performance of their transformers before committing to larger orders.

- Global Reach: Unicreed supplies transformers to major markets worldwide, including Europe, India, Russia, Türkiye, and Israel. Their global presence makes them a reliable partner for international businesses.

Conclusion:

After working closely with industrial automation systems, I’ve seen firsthand how much of a difference toroidal transformers can make. Their ability to reduce energy loss, operate quietly, and deliver consistent power has a direct impact on system efficiency and overall performance. Whether it’s minimizing downtime or saving space in control panels, the benefits are clear.

When selecting a toroidal transformer, I always consider voltage requirements, load capacity, and the operating environment. It’s essential to choose a design that fits your system’s specific needs and to work with a supplier that prioritizes quality and customization.

If you’re planning your next automation upgrade or developing a new system, I encourage you to contact us at Unicreed. We provide high-quality toroidal transformers designed for industrial performance. You can reach us at sales@unicreed-transformer.com or visit our website at www.unicreed-transformer.com. I’d be glad to help you find the right solution for a smarter, more efficient operation.