High-frequency transformers are essential components used in various electronic devices, including power supplies, converters, and inverters. They are used to transfer electrical energy between two or more circuits through electromagnetic induction. However, the performance of high-frequency transformers is often limited by the presence of leakage inductance. In this blog, we have discussed the definition and importance of reducing leakage inductance in high-frequency transformers.

High-frequency transformers are essential components used in various electronic devices to transfer electrical energy. However, the performance of high-frequency transformers can be limited by the presence of leakage inductance. It is, therefore, important to minimize the leakage inductance to improve the efficiency and reliability of the transformer. By reducing the leakage inductance, the performance of high-frequency transformers can be improved, leading to better energy efficiency, reduced voltage spikes, and improved overall performance.

What is leakage inductance, and why is it important to reduce it in high-frequency transformers?

Leakage inductance is the inductance that exists between the primary and secondary windings of a transformer, which does not contribute to energy transfer between them. It occurs due to the magnetic flux that does not link the windings and hence does not transfer energy. Leakage inductance can cause voltage spikes, reduce efficiency, and affect the overall performance of the transformer.

In high-frequency transformers, the presence of leakage inductance can be particularly problematic because it can result in higher energy losses and reduced efficiency. The higher frequency of operation in these transformers means that energy losses due to leakage inductance can be more significant than in low-frequency transformers. Additionally, the voltage spikes caused by leakage inductance can damage sensitive electronic components in the circuit, leading to reduced reliability and performance.

Therefore, it is important to reduce the leakage inductance in high-frequency transformers to improve their efficiency, reduce energy losses, and increase their reliability. By reducing the leakage inductance, the energy transfer between the primary and secondary windings can be improved, leading to better performance and increased reliability. Additionally, minimizing leakage inductance can help to reduce the size and weight of the transformer, making it more compact and cost-effective.

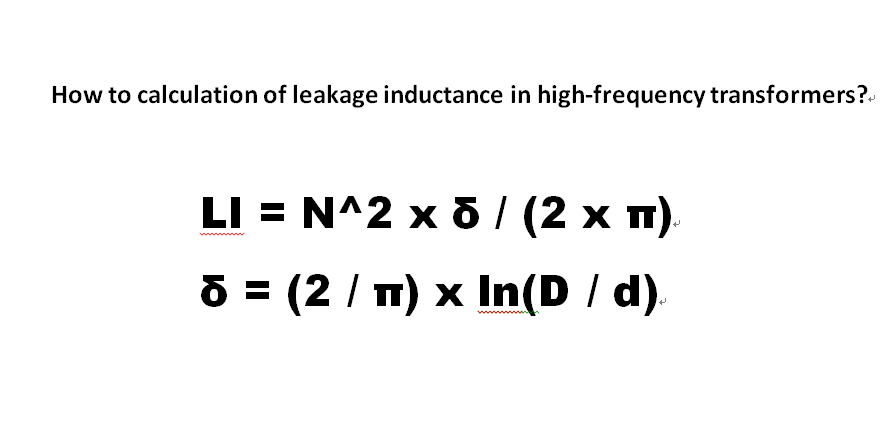

How to calculation of leakage inductance in high-frequency transformers?

The calculation of leakage inductance in high-frequency transformers can be done using the following formula:

Ll = N^2 x δ / (2 x π)

Where Ll is the leakage inductance in Henrys, N is the number of turns on either the primary or secondary winding, and δ is the winding factor.

The winding factor δ is a dimensionless parameter that takes into account the physical dimensions of the transformer’s windings. It is defined as the ratio of the actual magnetic flux linking the winding to the total flux produced by the winding’s current.

δ = (2 / π) x ln(D / d)

Where D is the outer diameter of the winding and d is the inner diameter.

To calculate the leakage inductance, the values of N and δ are first determined. Then the formula is applied to obtain the value of Ll. In high-frequency transformers, the leakage inductance is typically minimized by using interleaved windings, reducing the distance between the windings, and increasing the coupling between the windings. These design techniques can help to reduce the amount of magnetic flux that does not link the windings, thereby reducing the leakage inductance.

What are the common causes of high leakage inductance, and how can it affect the performance of a transformer?

There are several common causes of high leakage inductance in a transformer:

- Poor winding design: The winding design of a transformer can impact the level of leakage inductance. For example, if the windings are not interleaved, the distance between the primary and secondary windings may be greater, leading to higher leakage inductance.

- Magnetic core design: The shape and size of the magnetic core can also affect the leakage inductance. If the core is not properly designed or has gaps or irregularities, it can cause magnetic flux to leak, leading to higher leakage inductance.

- Insulation materials: Insulation materials used in the transformer can cause uneven winding, resulting in increased leakage inductance.

- Frequency of operation: High-frequency operation can also cause increased leakage inductance due to the skin effect and proximity effect, which create non-uniform distribution of the magnetic flux and thus contribute to leakage inductance.

The presence of high leakage inductance can negatively impact the performance of a transformer in several ways:

- Reduced efficiency: Leakage inductance can cause energy losses, leading to reduced efficiency and increased power consumption.

- Voltage spikes: Leakage inductance can cause voltage spikes during the switching of the transformer, which can damage sensitive electronic components in the circuit.

- Reduced regulation: The presence of high leakage inductance can cause the output voltage of the transformer to be less stable, leading to reduced regulation and poorer performance.

- Increased noise: Leakage inductance can also cause electromagnetic interference (EMI) or radio frequency interference (RFI), leading to increased noise in the circuit and potential signal distortion.

- Therefore, reducing leakage inductance is crucial for improving the performance and efficiency of high-frequency transformers.

What are some techniques that can be used to reduce leakage inductance in high-frequency transformers?

There are several techniques that can be used to reduce the leakage inductance in high-frequency transformers:

- Interleaved winding: One effective technique to reduce leakage inductance is to use interleaved winding. This involves alternating the winding layers between primary and secondary windings, which reduces the distance between the windings and increases the coupling between them.

- Multi-section winding: Using a multi-section winding can also reduce leakage inductance. This technique involves dividing the primary and secondary windings into several smaller sections, which are wound in a way to minimize the distance between them.

- Litz wire: Litz wire consists of multiple individually insulated strands of wire, which are woven together to form a single conductor. This technique reduces the skin effect and proximity effect, which can lead to lower leakage inductance.

- Magnetic core design: Proper magnetic core design can also reduce leakage inductance. The core should be designed to minimize air gaps and ensure a uniform magnetic flux distribution.

- Increased coupling: Increasing the coupling between the primary and secondary windings can also reduce leakage inductance. This can be achieved by using a higher turns ratio, using magnetic materials with higher permeability, or increasing the number of winding layers.

- Reduce frequency of operation: Reducing the frequency of operation can also help to reduce the leakage inductance. This can be achieved by using a lower frequency or by using a resonant converter.

What are the design considerations for reducing leakage inductance?

Reducing leakage inductance in high-frequency transformers requires careful consideration of the magnetic core design, winding design, wire selection, and shielding. By optimizing these factors, it is possible to minimize the leakage inductance and improve the performance and efficiency of high-frequency transformers.

- Magnetic core design: The magnetic core should be designed to minimize air gaps and ensure a uniform magnetic flux distribution. The core material should have a high permeability and low loss.

- Winding design: The winding design should be optimized to minimize the distance between the primary and secondary windings. This can be achieved through interleaved winding or by using a multi-section winding.

- Wire selection: The wire used for winding should have a high conductivity and low resistance to minimize the skin effect and proximity effect.

- Litz wire: Litz wire can be used to further reduce the skin effect and proximity effect. It consists of multiple individually insulated strands of wire, which are woven together to form a single conductor.

- Ferrite beads: Ferrite beads can be placed around the transformer windings to reduce the leakage inductance by absorbing the magnetic flux that leaks from the core.

- Shielding: Shielding can be used to prevent EMI and RFI interference, which can lead to increased noise and signal distortion.

- Frequency of operation: Reducing the frequency of operation can also help to reduce the leakage inductance. This can be achieved by using a lower frequency or by using a resonant converter.

- Coupling: Increasing the coupling between the primary and secondary windings can also reduce leakage inductance. This can be achieved by using a higher turns ratio or by increasing the number of winding layers.

How do design considerations like core material, winding turns ratio, wire gauge, and frequency affect leakage inductance in high-frequency transformers?

The following design considerations can affect leakage inductance in high-frequency transformers:

- Core Material: The permeability and saturation characteristics of the magnetic core material affect the magnetic flux density and, therefore, the amount of flux that leaks from the core. Choosing a material with a high permeability and low saturation flux density can reduce the leakage inductance.

- Winding Turns Ratio: The turns ratio between the primary and secondary windings determines the coupling coefficient, which affects the amount of magnetic flux that links between the windings. A higher turns ratio can increase the coupling coefficient and reduce the leakage inductance.

- Wire Gauge: The wire gauge affects the resistance and skin effect of the winding. Thicker wires have lower resistance and skin effect, which can reduce the leakage inductance. However, thicker wires can also increase the proximity effect and require more space to wind, which can increase the winding capacitance and reduce the coupling between the windings.

- Frequency: The frequency of the input signal affects the skin effect, proximity effect, and core loss of the transformer. Higher frequencies increase the skin and proximity effect, which can increase the leakage inductance. Additionally, high-frequency operation can lead to core loss due to hysteresis and eddy current losses, which can increase the temperature and reduce the efficiency of the transformer.

How can leakage inductance be measured and tested, and what are some common test methods?

Leakage inductance can be measured and tested using several methods. Some common test methods are:

- Open Circuit Test: In this method, the primary winding is energized with a low-voltage AC source, and the secondary winding is left open. The primary voltage and current are measured, and the primary inductance and core loss are calculated. The leakage inductance is calculated as the difference between the total inductance and the primary inductance.

- Short Circuit Test: In this method, the secondary winding is short-circuited, and the primary winding is energized with a low-voltage AC source. The primary voltage, current, and power are measured, and the core loss and magnetizing inductance are calculated. The leakage inductance is calculated as the difference between the total inductance and the magnetizing inductance.

- Impedance Test: In this method, the transformer is connected to a known impedance, and the primary and secondary currents and voltages are measured. The impedance includes the winding resistance, leakage inductance, magnetizing inductance, and load impedance. By measuring the impedance at different frequencies, the leakage inductance can be determined.

- Network Analyzer Test: In this method, the transformer is connected to a network analyzer, and the frequency response of the transformer is measured. By analyzing the frequency response, the leakage inductance and other characteristics of the transformer can be determined.

- Network Analyzer Test: In this method, the transformer is connected to a network analyzer, and the frequency response of the transformer is measured. By analyzing the frequency response, the leakage inductance and other characteristics of the transformer can be determined.

Are there any trade-offs between reducing leakage inductance and other design considerations like size, weight, and cost?

Yes, there are trade-offs between reducing leakage inductance and other design considerations like size, weight, and cost. For example, using a larger core and increasing the turns ratio can reduce the leakage inductance, but it also increases the size and weight of the transformer. Similarly, using thicker wire and higher-quality core materials can also reduce leakage inductance, but it can increase the cost of the transformer.

Reducing leakage inductance can also affect other performance parameters, such as efficiency and regulation. For example, increasing the turns ratio to reduce leakage inductance can improve the efficiency of the transformer but may also increase the regulation error

Therefore, the design of a high-frequency transformer involves optimizing multiple parameters to achieve a balance between performance, size, weight, and cost. The designer must carefully consider the application requirements and prioritize the design parameters accordingly.

What are some future directions for research on reducing leakage inductance in high-frequency transformers?

Research on reducing leakage inductance in high-frequency transformers is an ongoing area of interest. Some potential future directions for research in this area include:

- Advanced Core Materials: New core materials with better magnetic properties can reduce core losses and enable higher operating frequencies, leading to lower leakage inductance.

- Advanced Winding Techniques: Novel winding techniques, such as interleaved or bifilar winding, can reduce leakage inductance by distributing the magnetic field more evenly across the windings.

- Multi-Level Converter Topologies: Multi-level converter topologies can reduce voltage stress across the transformer and enable higher operating frequencies, leading to lower leakage inductance.

- Integrated Magnetics: Integrated magnetics involve integrating the transformer into the power electronic circuit, reducing parasitic inductance and improving overall efficiency.

- Soft-Switching Techniques: Soft-switching techniques, such as zero-voltage switching or zero-current switching, can reduce switching losses and enable higher operating frequencies, leading to lower leakage inductance.

- Machine Learning: Machine learning can be used to optimize transformer designs by predicting the impact of different design parameters on leakage inductance and other performance parameters.

In order to reduce leakage inductance, designers must carefully consider a range of design parameters, including core material, winding turns ratio, wire gauge, and operating frequency. While reducing leakage inductance can have a positive impact on the performance of a high-frequency transformer, there are trade-offs between this and other design considerations like size, weight, and cost.

Future research directions in this field include the development of advanced core materials, novel winding techniques, and soft-switching techniques, as well as the integration of magnetics into power electronic circuits and the utilization of machine learning to optimize transformer designs. By exploring these new avenues, researchers can continue to improve the performance of high-frequency transformers and their impact on power electronic applications.