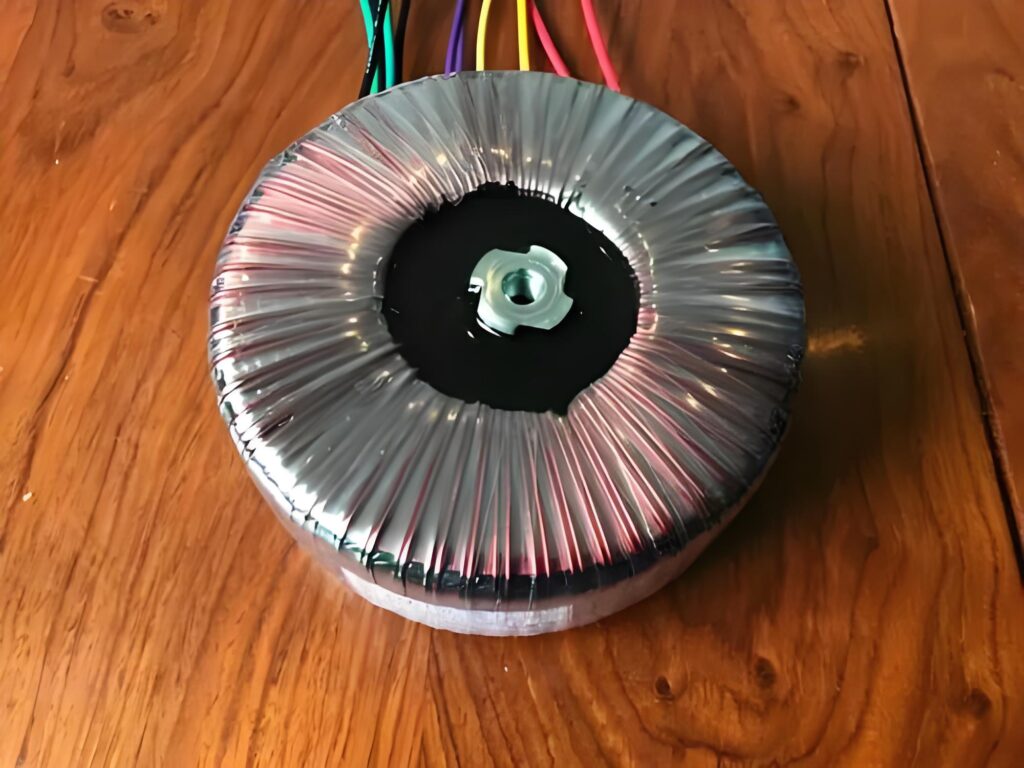

As someone deeply involved in transformer manufacturing, I’ve always been fascinated by the design of toroidal transformers. With their distinctive ring shape, they deliver excellent efficiency, low electromagnetic interference, and compact size. That’s why they’re widely used in industrial control systems, medical devices, audio systems, and many other critical applications.

But there’s a problem. Traditional toroidal transformers, while efficient, can still face challenges in demanding environments. Moisture, dust, vibration, and thermal stress can all impact performance and shorten service life. For industries that rely on precision and reliability, this is a serious concern.

This is where encapsulation comes in. By sealing toroidal transformers in protective resin, encapsulation adds a layer of defense and opens new possibilities for performance and durability. But how exactly does encapsulation improve a transformer’s performance? Let’s explore why this innovation is becoming a standard in modern transformer design.

What is Encapsulation in Toroidal Transformers?

Encapsulation in toroidal transformers refers to the process of completely sealing the transformer’s core and windings within a protective material such as epoxy resin or electrical-grade silica sand mixed with resin compounds. This encapsulation creates a robust barrier around the doughnut-shaped core and wire windings, isolating them from environmental factors like moisture, dust, dirt, and mechanical damage.

What’s the main Benefits of Encapsulation in Toroidal Transformers?

Have you ever wondered why encapsulation is considered a game-changer in toroidal transformer design?

Let’s explore the key benefits that make encapsulation an essential feature in modern toroidal transformers.

The main benefits of encapsulation in toroidal transformers include enhanced environmental protection against moisture, dust, and contaminants, which significantly improves durability. It provides superior electrical insulation and mechanical strength, increasing resistance to vibration and shock. Encapsulation also reduces electromagnetic interference (EMI) and noise, leading to quieter operation, while improving thermal management to maintain stable performance. Altogether, this results in longer lifespan, higher reliability, and efficiency, especially in demanding applications such as medical devices, industrial controls, and audio equipment.

How Encapsulation Protects and Improves Transformer Durability?

Have you ever wondered how transformers survive harsh environments like high humidity, dust, or constant vibration? These factors can easily damage traditional transformers and shorten their service life.

This is why encapsulation has become a key technology in modern transformer design. By sealing the core and windings in a protective resin, encapsulation creates a robust barrier against environmental and mechanical stress.

This process involves:

- Blocking moisture and dust to prevent insulation failure and corrosion.

- Absorbing vibration and shocks to protect delicate internal components.

- Enhancing thermal conductivity for better heat dissipation and longer operational life.

- Providing electrical insulation that improves overall safety and reliability.

With encapsulation, transformers are not only protected but also perform more consistently over time, even in the most demanding applications.

How Encapsulation Enhances Electrical Performance?

Encapsulation enhances electrical performance by providing superior insulation and stabilizing the internal environment, which prevents moisture and contaminants from affecting the core and windings. This stability reduces dielectric losses and helps maintain consistent electrical characteristics. Additionally, encapsulation mitigates electromagnetic interference (EMI) by containing stray magnetic fields, which complements the toroidal core’s natural EMI shielding. This results in minimal signal distortion and low electromagnetic noise, crucial for sensitive applications like audio equipment and medical devices. Encapsulated transformers also experience improved thermal management, allowing efficient heat dissipation, which lowers operating temperature and electrical resistance, further boosting efficiency and longevity. Altogether, these factors lead to higher energy efficiency, quieter operation, and enhanced signal integrity in encapsulated toroidal transformers.

The Benefits of Encapsulation in Real-World Applications

Have you ever wondered why encapsulated toroidal transformers are preferred in so many critical and demanding industries?

Let’s explore the real-world benefits that make encapsulated toroids the ideal choice across various applications.

Encapsulated toroidal transformers offer a compact and space-saving design, which is crucial where every millimeter counts. Their construction also leads to quieter operation by significantly reducing vibrations and humming noises, enhancing the overall user experience. These advantages translate into clear benefits in many fields:1.Medical equipment

1.Medical equipment

Sensitive to electromagnetic interference (EMI), these devices rely on encapsulated transformers to maintain precise signals and ensure patient safety.

2.Audio and recording devices

Minimal electrical noise and vibration are vital for high-fidelity sound reproduction, making quiet encapsulated toroids essential.

3.Industrial control panels

Dust, moisture, and vibration are common challenges in industrial settings, but encapsulation protects transformers to ensure consistent, reliable operation.

4.Renewable energy systems

Efficiency and reliability are critical for solar and wind power systems, where encapsulated transformers improve performance and durability.

5.Marine electronics

Facing harsh environments with humidity, salt spray, and temperature changes, encapsulated transformers provide the necessary protection and longevity.

Comparison: Encapsulated Toroidal Transformers vs. Non-Encapsulated

| Feature | Encapsulated Toroidal Transformers | Non-Encapsulated Toroidal Transformers |

| Protection | Fully sealed with heat-cured epoxy resin, protecting against moisture, dust, and contaminants. | Windings are exposed, vulnerable to dust, moisture, and environmental damage. |

| Noise and Vibration | Reduced mechanical humming and vibration noise due to encapsulation damping. | More prone to audible humming and vibrations because of exposed windings. |

| Durability and Reliability | Higher durability with enhanced resistance to mechanical shock, vibration, and environmental hazards. | Less durable in harsh environments, more susceptible to mechanical damage. |

| Thermal Management | Encapsulation materials aid heat dissipation, maintaining stable operating temperature. | Heat dissipation relies solely on core design; risk of hotspots if exposed. |

| Electromagnetic Interference (EMI) | Lower EMI emissions and better shielding effects due to encapsulation barrier. | Higher EMI leakage is possible, potentially affecting nearby sensitive electronics. |

| Size and Installation | Compact and self-contained unit, often with mounting kits for easy installation. | May require additional protective enclosures or shielding for safe use. |

| Applications Suitability | Ideal for sensitive or harsh environments (medical devices, audio equipment, industrial controls, marine). | Suitable for controlled, clean environments with minimal exposure risks. |

| Cost | Generally higher cost due to added materials and manufacturing processes. | Typically lower cost because of simpler construction. |

| Safety Standards Compliance | Often meets strict standards due to encapsulation; some meet specialized certifications (e.g., UL, EN). | May not meet stringent environmental or safety standards without extra measures. |

In summary, encapsulated toroidal transformers provide enhanced protection, quieter operation, improved thermal stability, and longer lifespan, making them ideal for demanding applications. Non-encapsulated versions can be adequate for less challenging environments but usually at the expense of noise control and durability.

Why Choose Unicreed Encapsulated Toroidal Transformers?

In industrial applications, reliability, safety and efficiency are critical for every power system. As a manufacturer with over 13 years of experience, Unicreed Electronics is committed to providing high-performance and highly stable solutions. Our encapsulated toroidal transformers are trusted by customers worldwide for their superior quality and performance.

Here are six key reasons why Unicreed toroidal transformers should be your first choice.

1.Premium Materials for Superior Performance

At Unicreed, we understand that great products start with great materials. That is why we use:

- Engineering plastic enclosures from BASF in Germany for excellent heat resistance and durability

- High purity copper wire from ELEKTRISOLA in Germany for superior conductivity

- Nippon Steel silicon steel cores from Japan for low energy loss and high efficiency

- High quality potting resin from WEVO-CHEMIE in Germany for perfect vacuum encapsulation

These premium materials ensure reliable performance even in demanding environments.

2.Strict Compliance with International Safety Standards

Unicreed toroidal transformers are designed to meet global certification requirements including:

- High dielectric strength up to 4200Vrms

- Flame retardant potting with UL94V-0 rating

- Temperature class B (130°C) insulation system

- Compliance with EN61558, EN60950, UL1585 and UL506 standards

This makes them ideal for medical devices, smart meters and industrial control systems where electrical safety cannot be compromised.

3.Compact Design with High Power Density

Compared with conventional EI transformers, the toroidal design provides several advantages:

- Smaller size and lighter weight for easy installation

- Minimal magnetic field interference and ultra-low noise

- Excellent load regulation and higher energy efficiency

- Power ranges from 20VA to 3000VA with customization available

This design is especially valuable for applications where space is limited and energy efficiency is critical, such as medical devices and green energy systems.

4.Designed for Demanding Industrial Applications

Whether your systems are used in industrial automation, renewable energy, solar power or elevator control systems, Unicreed toroidal transformers are built to operate reliably in ambient temperatures up to 70°C and under long-term high load conditions.

5.100% Tested for Quality Assurance

Every Unicreed transformer goes through a rigorous quality process including:

- 100% online electrical parameter testing

- High voltage dielectric strength and insulation tests

- Visual inspections to check for flawless appearance

- Outgoing quality control in compliance with GB2828 standards

This ensures that every product delivered to you is of the highest quality.

6.Global Reach and Flexible Customization

With five production lines and exports to Europe, India, Türkiye, Russia and Israel, Unicreed supports B2B customers worldwide. We provide OEM and ODM services with flexible design capabilities to meet your exact technical and regulatory requirements.

Compared to other brands, Unicreed offers:

- Better value for money without sacrificing quality

- Faster lead times from our in-house manufacturing

- Flexible minimum order quantities for OEM projects

Partner with Unicreed for Your Power Needs

Unicreed encapsulated toroidal transformers are the ideal choice for delivering safe, efficient and reliable power in every application. From medical devices and industrial automation to renewable energy systems, we provide professional solutions tailored to your needs.

📩 Contact us today at sales@unicreed-transformer.com

🌐 Visit our website at www.unicreed-transformer.com

Conclusion

Encapsulation plays a vital role in taking toroidal transformer performance to the next level. By protecting the windings and core from moisture, dust, and mechanical stress, it ensures greater durability, improved thermal management, and reliable operation even in the most demanding environments. For industries where efficiency and precision matter, this innovation is a game-changer.

At Unicreed, we have developed a full range of high-quality encapsulated toroidal transformers designed to meet the needs of industrial control systems, medical devices, audio equipment, and more. Each unit reflects our commitment to superior performance and long-lasting reliability.

If you are looking for transformers that can enhance your products and deliver peace of mind in operation, we are here to help. Contact us today to discuss how our transformers can enhance your applications.