Getting the right transformer for your product isn’t just about power,it’s about precision. In today’s world of advanced technology, even the smallest voltage mismatch can lead to reduced efficiency, overheating, or costly downtime. That’s why I always recommend looking beyond standard solutions when voltage requirements are critical.

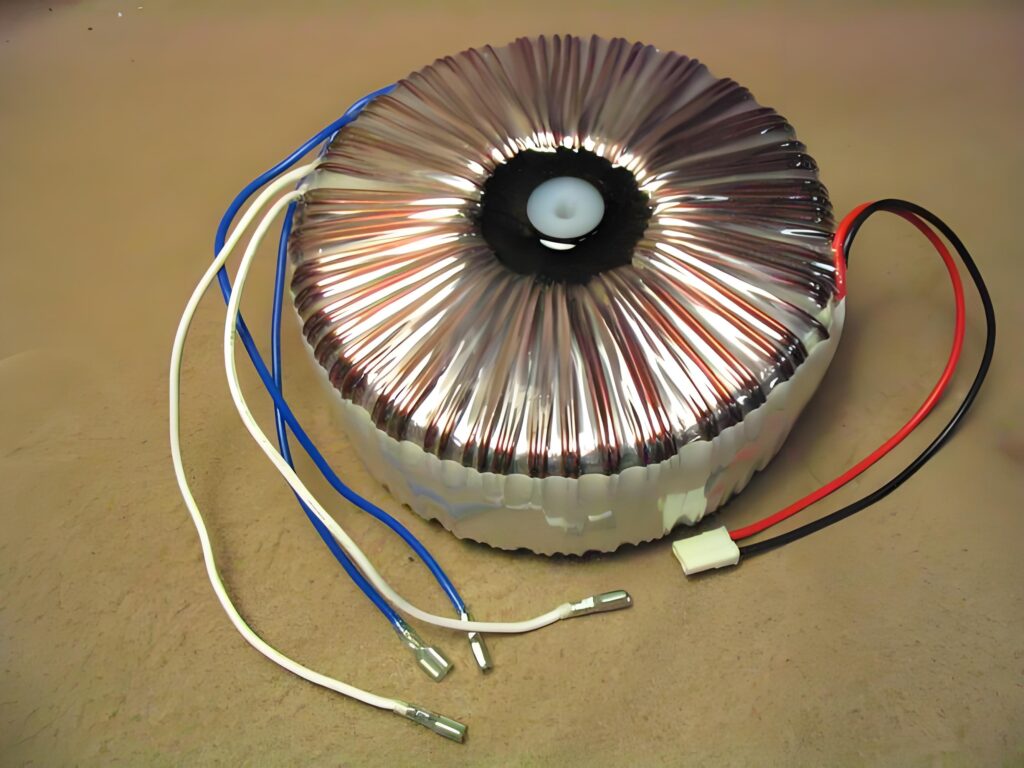

Toroidal transformers stand out for their compact design, high efficiency, and quiet operation. But here’s the real advantage: when customized, they can deliver exact voltage outputs tailored to your specific application whether it’s for medical devices, industrial controls, or renewable energy systems.

At Unicreed, I help businesses like yours design custom toroidal transformers that ensure your systems run smoothly and reliably. In this post, I’ll share how we design for specific voltage needs and why a custom solution could save you time, money, and headaches in the long run.

What is a toroidal transformer?

A toroidal transformer is a type of transformer that uses a donut-shaped (toroidal) magnetic core, around which the windings are uniformly wrapped. This design offers notable advantages compared to conventional laminated core transformers.

1.Key Benefits over Conventional Transformers

Higher Efficiency: Toroidal transformers typically achieve efficiencies between 90% to 97%, surpassing the less than 90% efficiency common in standard EI transformers. Their continuous core and optimized winding coverage minimize energy losses by reducing leakage flux and air gaps present in conventional designs.

Compactness and Lightweight: The circular core and tight winding make toroidal transformers smaller and lighter often about half the volume and weight of comparable conventional transformers. This makes them ideal for applications with space or weight constraints.

Low Electromagnetic Interference (EMI): The toroidal shape ensures a symmetrical, closed magnetic path, which significantly reduces magnetic flux leakage and radiated EMI. This quality is critical in reducing interference with nearby sensitive electronics.

Quieter Operation: Mechanical vibrations that cause transformer humming are minimized in toroidal cores because of their continuous, gapless construction and uniform winding. This results in very low noise levels, making them suitable for noise-sensitive environments like medical and audio equipment.

Ease of Mounting: Toroidal transformers can typically be mounted with a single bolt and allow for various custom mounting solutions, simplifying installation and reducing maintenance time.

2.Common Applications Requiring Custom Voltage Outputs

Custom toroidal transformers are especially useful when specific voltage, power, or mounting requirements are needed beyond standard products. Typical applications include:

- Medical Equipment: Requires low noise, high efficiency, and precise voltage outputs to avoid interference and ensure patient safety.

- Audio and High-Fidelity Equipment: Low hum and EMI are critical to maintaining sound purity.

- Industrial Control Systems: Custom voltages and higher power ratings are often necessary for specific control circuits or machinery.

- Telecommunications and IT Equipment: Compact size and efficient power conversion for sensitive and space-limited hardware.

- Renewable Energy Systems: Custom transformers may be designed to match various input/output voltage levels or power demands in solar or wind energy converters.

- Specialized Consumer Electronics: When reduced size and noise are important, such as in compact, portable, or premium devices.

Manufacturers like Unicreed offer custom design capabilities to deliver toroidal transformers with precise voltages, power ratings up to 15 kVA, and specialized mounting or enclosures tailored to the application.

When to Choose a Custom Toroidal Transformer for Specific Voltage Requirements

Have you ever wondered why sometimes standard transformers just don’t fit the bill when you have very specific voltage needs? Do you know how customizing a toroidal transformer can make all the difference in specialized applications?

Let’s explore when and why you should choose a custom toroidal transformer for specific voltage requirements.

You should choose a custom toroidal transformer for specific voltage requirements in the following 2 contexts:

1.Scenarios Where Off-the-Shelf Transformers Are Insufficient

Unique Voltage or Power Needs: Standard transformers often come with fixed input/output voltages and VA ratings, which may not perfectly match your application’s requirements especially if you need non-standard voltages or multiple secondary outputs (such as 24V, 30V, 40V or power ratings up to 15 kVA and beyond). Precise voltage and power levels are essential to avoid equipment overheating or overloading, making customization necessary.

Space Constraints: In applications like compact medical devices, audio equipment, or telecom hardware, physical size and mounting options are critical. Off-the-shelf transformers might not fit specific form factors or installation requirements, so custom designs provide the ideal solution.

Special Electrical or Environmental Conditions: Some uses demand low electromagnetic interference (EMI), high thermal stability, or regulated output voltages that generic models can’t guarantee. For example, medical-grade or audio devices require low noise and tightly controlled output, achievable only through custom transformers.

Higher Efficiency or Enhanced Performance: When energy efficiency is a priority such as in renewable energy systems or advanced industrial setups custom transformers designed for up to 97% efficiency offer significant energy savings and improved thermal management compared to standard products.

2.The Value of Customization for Unique Voltage, Current, or Physical Constraints

Tailored Electrical Parameters: Custom transformers allow exact adjustment of primary and secondary voltages, current ratings, turns ratios, and VA power ratings. This precision ensures stable, reliable operation even under peak load, minimizing risk of under or over powering your equipment.

Optimized Thermal and Mechanical Design: With custom core materials and winding layouts, these transformers can dissipate heat better, weigh as much as 50% less, and be shaped to fit unique mounting or enclosure specifications vital for durability and ease of installation.

Reduced EMI and Noise: Customized shielding and winding techniques further lower electromagnetic interference and audible hum critical for sensitive electronics in medical and audio applications.

Flexibility for Industry-Specific Standards: Custom toroidal transformers can be built to meet necessary certifications (UL, CSA, TUV) and include special features like medical-grade insulation or custom terminals, ensuring compliance with stringent regulatory requirements.

This is why choosing a custom toroidal transformer is the best way to meet specific voltage requirements while optimizing size, efficiency, performance, and safety in your application.

Why a Custom Toroidal Transformer is the Best Fit for Your Voltage Specifications

Have you ever wondered why off-the-shelf transformers sometimes fail to meet the precise voltage needs of your equipment? Do you know how a custom toroidal transformer can offer the exact specifications required for optimal performance?

Let’s explore why a custom toroidal transformer is the best fit for your voltage specifications.

A custom toroidal transformer is ideal because it can be precisely engineered to your unique voltage, current, and physical requirements, ensuring maximum efficiency and reliability. Here are 5 keys reasons:

- Perfect Match for Unique Voltage and Power Needs: Unlike standard transformers with fixed voltages and power ratings, custom transformers can be designed for specific input and output voltages including uncommon or multiple secondary voltagesand power capacities up to 15 kVA or more, preventing equipment damage and inefficiencies.

- Compact and Tailored Mechanical Design: Customized cores and winding structures allow the transformer to fit into restricted spaces, match exact mounting needs, and reduce weight significantly advantages crucial in medical, audio, or telecom devices where size and installation flexibility matter.

- Superior Electrical Performance and Stability: Custom designs optimize turns ratio, wire gauge, and core materials to deliver stable voltage under varying loads while minimizing losses, ensuring equipment operates safely and consistently.

- Reduced Electromagnetic Interference and Noise: Custom shielding and winding arrangements help lower EMI and audible hum, essential for sensitive electronics such as robotics or medical equipment where electromagnetic compatibility is critical.

- Compliance and Safety: Custom transformers can be built to meet strict industry standards and certifications, with features like medical-grade insulation or specialized terminals that off-the-shelf models lack.

What to Consider When Designing a Toroidal Transformer?

When designing a toroidal transformer, it’s essential to consider several key factors to ensure it delivers precise performance and meets strict safety standards. By carefully evaluating these elements, we can develop a transformer that is not only efficient and reliable but also compact and perfectly suited to the application’s specific voltage and power needs. Below 5 keys consider for your reference:

1.Input and Output Voltage Requirements

First, I clearly define the input (primary) and output (secondary) voltages. This is essential because the number of coil turns depends directly on these voltages, following Faraday’s law of electromagnetic induction. Precise voltage specifications ensure the transformer delivers the right EMF without saturation or voltage drops under load.

2.Power Rating (VA), Current Requirements, and Duty Cycle

Next, I calculate the power rating in volt-amperes (VA), which is the product of output voltage and current under full load. I also examine current requirements carefully, since wire gauge and winding design depend on them. If the transformer will duty cycle (operate intermittently), I can sometimes size it smaller because the thermal stress is reduced, but I must consider how the output voltage may drop under surge currents.

3.Frequency of Operation and Its Impact on Size and Efficiency

The operating frequency greatly impacts transformer size and efficiency. Higher frequencies allow smaller core sizes due to reduced magnetic flux requirements. For example, a 60 Hz transformer can be about 20% smaller than a 50 Hz one. However, higher frequencies may increase core losses, so I balance size reduction with efficiency goals.

4.Core Selection: Material, Shape, and Cross-Sectional Area

Choosing the right core is vital. Toroidal cores are typically circular in cross-section, which helps minimize winding resistance and noise. I pick core materials based on performance and budget; premium virgin steel offers better magnetic properties but at higher cost, while recycled steel is cheaper with some trade-offs. The core’s cross-sectional area is sized to handle the magnetic flux density without saturating during normal operation, calculated using established formulas involving frequency, flux density, and turns per volt.

5.Primary-Secondary Isolation and Safety Considerations

Finally, I ensure there is proper insulation and isolation between primary and secondary windings, as well as between windings and the core. Good insulation prevents short circuits and ensures compliance with international safety standards like IEC. I also design creepage distances, insulation thickness, and mechanical mounting to maintain safety and durability over the transformer’s operational life.

How to Step-by-Step Process for Designing Toroidal Transformers with Specific Voltage Requirements?

Have you ever wondered how engineers design toroidal transformers that perfectly meet specific voltage requirements? Do you know what precise steps are involved to ensure the transformer delivers the right performance every time?

Let’s explore the step-by-step process for designing toroidal transformers with specific voltage requirements. Below 7 step you must to that:

1.Define Electrical Specifications

The first step is to clearly determine your input (primary) and output (secondary) voltages along with the required power rating (VA). This information sets the foundation for all the subsequent design calculations.

2.Select the Core

Next, I choose the right core material and size. The core’s cross-sectional area must be large enough to avoid magnetic saturation at the operating frequency. The shape typically circular for toroidal transformers helps reduce losses and noise.

3.Calculate Turns per Volt

Using Faraday’s law, I calculate how many wire turns correspond to one volt on the primary winding. This depends on the core’s magnetic properties and operating frequency. Ensuring the correct turns per volt ratio is essential for achieving precise voltage levels.

4.Determine Number of Turns for Windings

Then, I determine the total number of turns for both primary and secondary windings based on required voltages and the turns per volt value. This sets the turns ratio which defines the voltage transformation.

5.Select Wire Gauge and Winding Configuration

I select the appropriate wire gauge that can safely carry the current at the rated VA without excessive heating. The winding layout on the toroidal core must also minimize losses and electromagnetic interference.

6.Address Insulation and Safety Measures

At this stage, I decide on insulation materials and spacing between primary and secondary to meet safety standards, preventing short circuits or leakage currents.

7.Prototype and Test

Finally, after assembling the transformer, I prototype and rigorously test it under load conditions to verify voltage accuracy, efficiency, thermal performance, and compliance with required regulations.

Case Example: Designing a Custom Specific VoltageToroidal Transformer

Have you ever wondered how a custom toroidal transformer is designed step-by-step to meet specific voltage and power needs? Let’s walk through a real example of designing a transformer with an input voltage of 230V, an output voltage of 24V, and a power rating of 100VA

Step 1: Define Electrical Specifications

- Primary voltage: 230V (AC mains)

- Secondary voltage: 24V (desired output)

- Power rating: 100VA (volt-amps)

These specs form the foundation of the design.

Step 2: Core Selection

For 100VA at 50/60Hz, I select a toroidal core with an appropriate cross-sectional area typically around 15-20 cm² — made of high-quality silicon steel to minimize losses and avoid saturation.

Step 3: Calculate Turns per Volt

Using Faraday’s law and typical values for toroidal cores, turns per volt (TPV) is calculated.

For example, at 50Hz and a magnetic flux density around 1 Tesla, TPV ≈ 4.4 turns/volt.

- Primary turns = 230V × 4.4 = 1,012 turns

- Secondary turns = 24V × 4.4 = 106 turns

Step 4: Select Wire Gauge

Calculate currents:

- Secondary current = 100VA ÷ 24V ≈ 4.17A

- Primary current = 100VA ÷ 230V ≈ 0.43A

Choose wire gauges that handle these currents with low resistance and safe thermal limits — e.g., AWG 18 for secondary and AWG 24 for primary.

Step 5: Winding and Insulation

Wind the primary and secondary coils evenly and insulated to minimize leakage inductance and electromagnetic interference. Ensure proper insulation layers between windings and from the core for safety.

Step 6: Assembly and Testing

Assemble the transformer, mount it securely, and perform load tests:

- Verify that the output is stable at 24V under rated load (100VA).

- Measure temperature rise to ensure safe operation.

- Check for efficiency and minimal hum or EMI.

By carefully calculating core size, turns, wire gauge, and insulation, this custom toroidal transformer meets the exact specification of 230V to 24V at 100VA with high efficiency, low noise, and compact size.

This methodical approach ensures that custom transformers deliver precise voltages tailored to your application’s needs.

Why Choose Unicreed for Custom Specific Voltage Transformer Design?

Highlight Unicreed’s experience in producing toroidal transformers (15-1000VA range).

At Unicreed, I’ve seen how the right transformer can make or break a product’s performance. That’s why we specialize in designing and manufacturing custom toroidal transformers that meet your exact voltage and power requirements.

With years of experience, we produce toroidal transformers ranging from 15VA to 1000VA, serving diverse applications across industries. Whether you need a single voltage output or multiple secondary windings, we can tailor the design to fit your system perfectly.

Here’s why so many customers trust us:

- Flexible customization for voltage and power ranges to suit complex designs.

- Global certifications (CE, RoHS, UL) for international compliance.

- High efficiency and low magnetic noise, ideal for sensitive equipment.

- Proven collaboration with industries like medical devices, renewable energy, and industrial automation.

Conclusion:

Designing toroidal transformers for specific voltage requirements isn’t just about meeting technical specs, it’s about ensuring your systems perform with maximum efficiency, reliability, and safety. As we’ve seen, a custom solution allows you to address the unique challenges of your application, whether it’s in medical devices, industrial automation, or renewable energy systems.

At Unicreed, I work closely with customers to turn their voltage and performance requirements into a transformer design that fits seamlessly into their products. Our engineering team is here to help you create a solution that’s not only precise but also cost-effective and compliant with international standards.

If you’re ready to take the next step and ensure your systems run exactly as they should, let’s talk. Contact us today to design your voltage-specific toroidal transformer.