When designing systems like medical devices, control panels or solar inverters, choosing the right transformer can make or break your application. Yet many engineers and buyers face the same issue: should I go with a toroidal transformer or an EI core transformer? The wrong decision can lead to higher energy loss, excessive noise or even shortened equipment life.

I have seen firsthand how frustrating this can be, especially when you are balancing performance, size, cost and compliance. Each transformer type has its own strengths, but without a clear understanding, it is easy to end up with a mismatch.

That is why I am here to simplify the choice. In this post, I will walk you through the key differences between toroidal and EI core transformers, explain where each one fits best, and help you make an informed decision that supports your system’s performance and reliability. Let’s find the right transformer for your next project.

What Are Toroidal Transformers?

Core Design

Toroidal transformers are a special type of electrical transformer characterized by their unique doughnut-shaped core. This core is made from high-quality materials such as cold-rolled silicon steel, which is tightly wound into a circular loop. Unlike traditional laminated cores, the toroidal design eliminates air gaps, creating a continuous magnetic circuit that minimizes magnetic resistance and energy losses. The circular shape not only enhances efficiency but also reduces noise and vibration, making toroidal transformers ideal for applications requiring quiet operation and compact designs.

Overview of Their Construction

The construction of toroidal transformers is both innovative and practical. The primary and secondary windings are wrapped directly around the toroidal core, ensuring close alignment with the magnetic circuit. This arrangement improves coupling between the windings and reduces leakage flux, which enhances efficiency. Insulating layers are placed between the windings to prevent short circuits and ensure safety. The compact design allows for shorter winding lengths, reducing copper usage and overall transformer size.

Toroidal transformers offer a range of performance advantages that make them ideal for modern electrical and electronic applications. Among their most notable strengths are their compact design, high energy efficiency, and ability to minimize electromagnetic interference (EMI).

1.Compact Size

The doughnut-shaped core allows for efficient use of space, making toroidal transformers significantly smaller than conventional transformers with similar power ratings. This compactness is particularly valuable in space-constrained applications like medical devices and audio equipment.

2.High Efficiency

With efficiency levels reaching up to 95–99%, toroidal transformers minimize energy losses due to their continuous magnetic circuit and reduced core resistance. This makes them ideal for energy-sensitive applications.

3.Low Electromagnetic Interference (EMI)

The design confines the magnetic flux within the core, drastically reducing stray fields and EMI. This feature ensures that nearby sensitive electronics, such as audio systems or control panels, are not disrupted

What Are EI-Core Transformers?

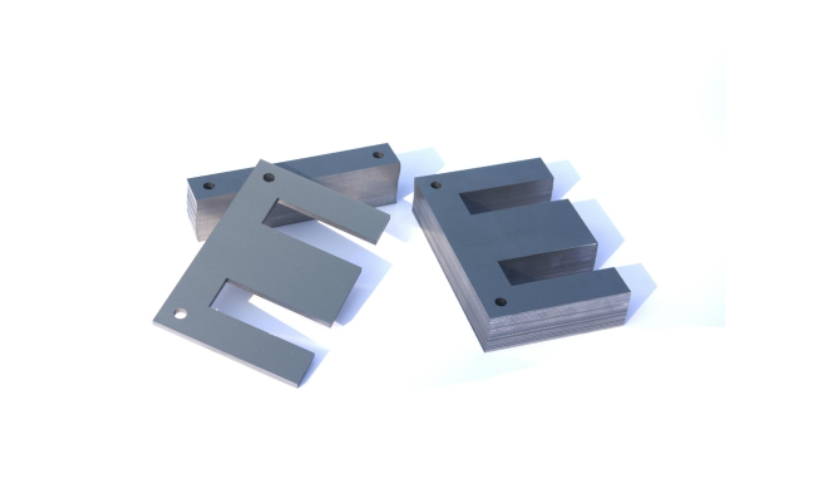

EI-core transformers are a widely used type of electrical transformer, named after the distinctive shape of their core laminations, which resemble the letters “E” and “I.” These transformers rely on a laminated rectangular core made of thin sheets of silicon steel. The lamination process is critical for reducing energy losses caused by eddy currents, which are induced by the alternating magnetic field in the core. By stacking these E- and I-shaped laminations together, the core forms a complete magnetic circuit that efficiently transfers energy between the primary and secondary windings. This design is particularly common in power supplies, audio equipment, and industrial applications due to its simplicity and effectiveness.

Construction Details: Stacked Iron Sheets Forming E and I Shapes

The construction of an EI-core transformer involves stacking thin sheets of silicon steel to form alternating “E” and “I” shapes. These sheets are coated with an insulating material, such as lacquer, to prevent electrical conductivity between adjacent layers. The E-shaped laminations provide slots for winding the primary and secondary coils, while the I-shaped laminations complete the magnetic circuit by covering the open ends of the E-shaped core. This layered structure minimizes eddy current losses by breaking up the conductive path within the core, forcing eddy currents to flow in smaller loops. Additionally, the use of high-grade silicon steel enhances magnetic permeability and reduces hysteresis losses, improving overall efficiency.

Known for their practical design and reliable performance, these components stand out for their cost-effectiveness, long-lasting durability, and broad versatility across a wide range of applications.

1.Cost-Effectiveness

EI-core transformers are relatively inexpensive to manufacture due to their simple construction process and widespread availability of materials like silicon steel. This makes them a cost-effective solution for a wide range of applications.

2.Durability

The laminated structure not only reduces energy losses but also enhances the durability of the transformer by minimizing heat buildup in the core. This ensures reliable operation over extended periods, even in demanding environments.

3.Versatility

EI-core transformers are highly adaptable and can be used in various applications, including power supplies, household appliances, audio equipment, and industrial machinery. Their ability to handle different voltage levels and power requirements makes them a versatile choice across industries.

Key Differences Between Toroidal and EI-Core Transformers

1.Design and Construction

- Toroidal: Compact, circular core; primary and secondary windings overlap

- EI-Core: Laminated rectangular core; windings on separate bobbins

2.Performance Characteristics

- Toroidal: Higher efficiency, lower heat generation, minimal signal distortion

- EI-Core: Lower inrush current, robust design for heavy-duty applications

3.Size and Weight

- Toroidal: Smaller, lighter; ideal for space-constrained setups.

- EI-Core: Larger, heavier; suitable for industrial environments

4.Cost Factors

- Toroidal: Higher upfront cost due to design complexity

- EI-Core: More affordable; widely used in general-purpose applications

How to Choose Toroidal or EI-Core Transformers for Your Application?

Applications of Each Transformer Type

Understanding where each transformer type performs best can help ensure system reliability and cost-efficiency. Below is a closer look at how toroidal and EI-core transformers are used across various industries and applications.

Toroidal Transformers

Toroidal transformers are especially well-suited for sensitive and high-performance electronics. Their low electromagnetic interference (EMI), compact design, and high efficiency make them the ideal choice for precision environments.

| Feature | Description | Applications |

| Compact Design | The doughnut-shaped core allows for efficient use of space, making them smaller and lighter than traditional transformers | Audio equipment, medical devices, renewable energy systems |

| High Efficiency | Achieves up to 95–99% efficiency due to superior magnetic flux containment and reduced core losses | Suitable for energy-sensitive applications like power inverters and UPS systems |

| Low Electromagnetic Interference (EMI) | The closed-loop magnetic path minimizes stray fields, reducing EMI and noise levels | Ideal for audio amplifiers, preamps, medical imaging devices, and CRT systems |

EI-Core Transformers

EI-core transformers are widely used in industrial and power-heavy applications due to their rugged construction, lower cost, and ease of maintenance. They are built to last and handle a wide range of power levels with consistent performance.

| Feature | Description | Applications |

| Cost-Effectiveness | Simple construction using laminated E- and I-shaped sheets makes them economical to produce | Industrial control systems, heavy machinery, power distribution grids |

| Durability | Laminated core structure reduces heat buildup and ensures reliable operation in harsh environments | Long-term use in high-power systems like transformers for factories or substations |

| Versatility | Can handle a wide range of voltage levels and power requirements due to their robust design | Suitable for large-scale power distribution and heavy-duty industrial machinery |

Advantages and Disadvantages

When comparing toroidal transformers with EI-core transformers, it’s important to evaluate several critical factors such as efficiency, physical size, cost, electromagnetic interference (EMI), and typical application scenarios. The table below provides a concise overview of these attributes, offering a clear comparison to help you better understand the strengths, limitations, and ideal use cases of each transformer type.

| Feature | Toroidal Transformers | EI-Core Transformers |

| Core Design | Doughnut-shaped core made from a continuous loop of magnetic material. | Laminated core consisting of stacked E- and I-shaped sheets. |

| Efficiency | Typically 90–95% efficient, with some designs reaching up to 97%. | Generally less than 90% efficient. |

| Electromagnetic Interference (EMI) | Low EMI due to compact shape and reduced magnetic flux leakage. | Higher EMI compared to toroidal transformers. |

| Size and Weight | Smaller and lighter, ideal for space-constrained applications. | Larger and heavier, suitable for applications where size is not a concern. |

| Noise Level | Quieter operation due to reduced vibration and hum. | Noisier due to vibration and hum from laminated core. |

| Manufacturing Complexity | More complex manufacturing process due to winding technique. | Simpler construction using standard laminations. |

| Cost | Generally more expensive due to specialized materials and manufacturing. | Cost-effective due to simpler design and materials. |

| Applications | Ideal for audio equipment, medical devices, and renewable energy systems where efficiency and low noise are critical. | Suitable for industrial control systems, heavy machinery, and power distribution grids. |

When selecting between toroidal and EI-core transformers, understanding their respective strengths and weaknesses is crucial for choosing the right type for your application. The following table summarizes the advantages and disadvantages of both:

| Toroidal Transformers | EI-Core Transformers | |

| Advantages | ||

| High Efficiency | Achieves up to 95–99% efficiency due to reduced core losses and optimized winding coverage | Generally less efficient, with energy losses in corners of the laminated core structure, typically below 90% |

| Reduced Electromagnetic Interference (EMI) | Low EMI due to the closed-loop core design that confines magnetic flux within the transformer, ideal for sensitive electronics like audio and medical devices | Higher EMI due to stray magnetic fields escaping from the laminated core, making them less suitable for sensitive applications |

| Compact Size | Smaller and lighter design (up to 50% lighter than EI-core transformers), ideal for space-constrained applications like renewable energy systems | Bulkier design, limiting use in compact electronics but suitable for larger industrial systems |

| Cost-Effectiveness | Higher initial cost due to complex manufacturing processes and premium materials | Economical design with lower production costs, making them ideal for budget-sensitive applications |

| Durability | Operates cooler and quieter, reducing wear and extending lifespan in sensitive environments25. | Robust construction ensures reliability in demanding industrial environments like power grids and heavy machinery13. |

| Versatility | Ideal for low kVA-rated devices (up to 15 kVA) used in medical, audio, industrial, and renewable energy applications | Suitable for high-power applications like industrial control systems and power distribution grids |

| Disadvantages | ||

| Higher Cost | More expensive due to specialized materials and manufacturing processes | Lower cost makes them a preferred choice for budget-sensitive applications |

| Complex Manufacturing Process | Requires advanced techniques for winding coils around the doughnut-shaped core, increasing production complexity | Simpler construction using standard laminated cores reduces production time and cost |

| Noise Level | Quieter operation due to reduced vibration and hum from the toroidal design | Noisier operation caused by magnetostriction and vibrations in laminated cores |

Choosing the Right Transformer for Your Application

Selecting the right transformer is essential for ensuring optimal performance, reliability, and cost-efficiency. Here’s how to approach this decision based on three critical factors:

1.Evaluate Your Application Requirements

The first step in choosing a transformer is to assess the specific needs of your application. This includes considering size constraints, noise sensitivity, and environmental conditions.

| Requirement | Considerations |

| Size Constraints | Compact applications like medical devices or audio equipment require smaller transformers such as toroidal transformers. Larger industrial systems may accommodate bulkier EI-core transformers. |

| Noise Sensitivity | Noise-sensitive environments, such as audio systems or control panels, benefit from toroidal transformers due to their quiet operation and reduced electromagnetic interference (EMI). |

| Environmental Conditions | Harsh environments, such as outdoor installations or corrosive industrial settings, require transformers with additional protection against heat, humidity, and dust. Liquid-filled units may be ideal for such conditions |

2.Consider Your Budget and Long-Term Operational Costs

Balancing upfront costs with long-term savings is crucial when selecting a transformer.

| Cost Factor | Toroidal Transformers | EI-Core Transformers |

| Initial Cost | Higher due to complex manufacturing processes and premium materials | Lower due to simpler construction and widely available materials |

| Operational Efficiency | High efficiency reduces energy waste, lowering long-term operational costs | Less efficient, leading to higher energy losses and increased operating costs over time |

| Maintenance Costs | Minimal maintenance required due to durable design and lower heat generation | May require more frequent maintenance due to higher heat buildup and wear in industrial settings |

3.Match the Transformer Type to Your Industry Needs

Different industries have unique requirements that dictate the type of transformer best suited for their applications.

| Industry/ApplMedical Devicesication | Recommended Transformer Type |

| Medical Devices | Toroidal transformers are preferred for their compact size, low noise levels, and high efficiency, ensuring reliable operation in sensitive equipment like imaging systems or monitors |

| Audio Equipment | Toroidal transformers excel in audio systems due to their reduced EMI and quiet operation, preserving signal integrity for high-fidelity sound reproduction |

| Industrial Machinery | EI-core transformers are ideal for heavy machinery and power distribution grids due to their durability and cost-effectiveness in handling high power loads |

| Renewable Energy Systems | Toroidal transformers are favored for renewable energy applications like inverters and solar power systems where efficiency and compactness are crucial |

Why Choose Unicreed Transformers?

1.In-House Manufacturing with Customizable OEM Solutions

Unicreed offers complete in-house manufacturing, allowing for tight control over quality, lead times, and design flexibility. Whether you need standard configurations or fully customized solutions, we welcome OEM and tailored orders to meet your exact technical and branding requirements. From concept to production, our team works closely with you to deliver transformers built precisely for your application.

2.International Certifications for Global Compliance

All Unicreed transformers are certified to meet key international standards, including VDE, CE, CQC, UL, CUL, and ROHS. These certifications ensure our products comply with global safety, quality, and environmental regulations—giving you confidence in both performance and regulatory readiness, no matter where your products are sold or installed.

3.Proven Global Export Experience with Strict Quality Control

With successful export operations across Europe, India, Russia, Türkiye, and Israel, Unicreed understands the needs of international markets. We combine fast turnaround production with rigorous quality control, including 100% testing of all transformers before shipment. This ensures every unit delivers reliable performance and meets customer expectations, consistently and efficiently.

If you are unsure which transformer type is right for your application, our team at Unicreed is here to help. You can reach us by email at sales@unicreed-transformer.com or visit our website www.unicreed-transformer.com for professional guidance and custom solutions.

Conclusion:

Choosing between a toroidal transformer and an EI core transformer really comes down to your specific application needs. If your project requires high efficiency, compact size and low noise such as in audio systems or medical devices, a toroidal transformer may be the better fit. On the other hand, if you are looking for something cost effective, durable and easy to mount for industrial control panels or alarm systems, an EI core transformer might be your best option.

Of course, every application is different, and making the right choice can save time, money and effort in the long run. If you are still unsure which type suits your project best, I invite you to contact us at Unicreed. Our team is ready to help you select or customize the ideal transformer for your needs. Let us work together to power your success.

You can reach us by email at sales@unicreed-transformer.com or visit our website www.unicreed-transformer.com to learn more.