Elevator control systems are some of the most demanding environments I have worked with. They rely on transformers to deliver stable and consistent power to drives, controllers, door mechanisms, and safety circuits, running continuously under changing loads. When the transformer is not the right fit, I have seen the consequences clearly system faults, unstable power, and failed safety checks.

In such a safety-critical application, selecting the wrong transformer is never a small mistake. It can lead to unexpected downtime, compliance failures, or serious safety risks. That is why I treat transformer selection as a key design decision in every elevator project.

With more than 13 years of experience, Unicreed knows exactly what elevator systems require. We have supplied customized transformers for lift control panels, door systems, and emergency power units, helping customers build safer and more reliable systems. In this blog, I will share what I look for when choosing the right transformer for elevator applications.

Once I understand the role transformers play in elevator control systems, the next step is choosing the right one. This is not just about matching voltage every detail matters, from power handling to space constraints, to meeting safety standards. Over the years, I have developed a simple checklist that helps me make the right decision for each project.

Here are the 7 key steps I follow when selecting a transformer for elevator control systems:

- Step 1: Assess Power and Load Requirements

- Step 2: Select Voltage and Frequency Configuration

- Step 3: Prioritize Core Type and Mechanical Design

- Step 4: Ensure Thermal and Efficiency Optimization

- Step 5: Assess Environment and Reliability

- Step 6: Prioritize Safety Certifications and Protections

- Step 7: Customization and Supplier Support

Step 1: Assess Power and Load Requirements

The foundation of any transformer choose begins with understanding your system’s actual power needs. In elevator control systems, different components operate under varying loads some continuously, others only during specific actions like door operation or emergency mode. Without accurate load assessment, you risk underpowering critical systems or overpaying for oversized units.

tart by calculating the total VA (Volt-Ampere) requirements of your elevator system. Break it down into:

- Continuous loads, such as control boards, signal indicators, lighting, and communication circuits.

- Intermittent peak loads, including door actuators, relays, brakes, and emergency motors.

To ensure long-term reliability and prevent voltage sag during sudden current spikes, it’s important to add a 25–50% safety margin. This extra headroom protects against inrush currents, future load expansions, and higher ambient temperatures.

Also, consider your elevator type:

- Single-phase transformers are typically sufficient for low-rise or hydraulic elevators.

- Three-phase transformers are often needed for high-speed, high-rise elevator systems with more demanding control and drive setups.

By accurately assessing your system’s power profile from the start, you ensure the transformer you choose delivers stable performance under all conditions without overheating, stalling, or degrading over time.

Step 2: Select Voltage and Frequency Configuration

Once you’ve calculated your power and load needs, the next critical step is aligning the transformer’s voltage and frequency settings with the building’s electrical infrastructure. Elevator systems are deployed across different regions, so flexibility and compatibility with local power grids is essential for both functionality and future maintenance.

Step 2: Select Voltage and Frequency Configuration

Start by matching the primary input voltage and frequency to the local mains supply:

For example, 400V 50Hz is common across Europe, while 480V 60Hz is typical in North America.

To support international or modular installations, many of Unicreed’s transformers offer dual-voltage primaries (e.g., 230V/400V), giving you greater flexibility and reducing stock variation.

Next, define your secondary voltages based on the specific functions in the elevator system:

- 24V DC for sensitive control circuits

- 110V AC for relays and signal equipment

- 230V AC for auxiliary motors or fan units

These secondary windings should be electrically isolated to prevent noise coupling and interference between control and power circuits a critical feature in modern elevator electronics.

For certain non-isolated applications where cost is a constraint, you may also consider auto-transformers. These can save space and money but are best used in non-critical or internally protected systems.

Choosing the right voltage and frequency configuration ensures stable operation, minimizes electrical noise, and guarantees compliance with regional standards all of which are key in safety-critical elevator applications.

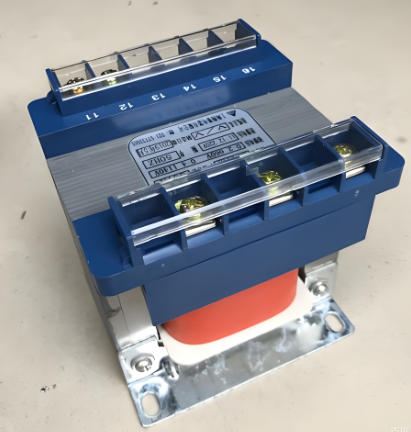

Step 3: Prioritize Core Type and Mechanical Design

With power and voltage configurations locked in, prioritizing the right core type and mechanical design is essential for transformers to survive the relentless vibration, dust, and temperature extremes of elevator environments while integrating flawlessly into control panels. This step ensures durability, minimal noise, and easy installation without compromising on performance in safety-critical systems.

Toroidal vs EI/UI Cores for Application Fit

Core type selection directly impacts noise, EMI, and mechanical resilience based on installation location.

- Toroidal cores deliver superior low hum and EMI performance, making them ideal for passenger cabins or areas near operators where audible buzz or electrical interference could annoy users or disrupt sensitive indicators.

- EI or UI laminated cores provide unmatched ruggedness for machine rooms, resisting high vibration from hoist motors, door slams, and seismic events better than toroids in harsh industrial conditions.

Match the core to the environment toroids for quiet zones, EI/UI for high-stress durability to optimize longevity and compliance

IP54+ Enclosure Ratings for Harsh Conditions

Elevator shafts and machine rooms expose transformers to contaminants and thermal swings, requiring sealed protection.

- IP54 or higher enclosures (dust-protected, water splash-resistant) with full encapsulation or epoxy potting block out grit, oil, and humidity that cause winding failures over time.

- Specify operation from -20°C to 70°C with Class F/H insulation to handle winter lows, summer heat buildup (often 50°C+ ambient), and proximity to hot VFDs without derating.

These ratings safeguard against environmental ingress, ensuring reliable 24/7 operation in unserviced areas.

Custom Mounting and Termination Options

Seamless fit in crowded cabinets demands tailored mechanical interfaces.

- Mounting solutions like DIN rail adapters for quick panel snaps, chassis bolts with isolators, or baseplates align perfectly with standard enclosures, absorbing vibration to prevent loosening.

- Termination choices screw terminals for reliability, flying leads (heat-resistant silicone), or keyed connectors match existing harnesses, speeding assembly in tight spaces under 300mm deep.

Step 4: Ensure Thermal and Efficiency Optimization

Beyond size and shape, a transformer must also handle heat efficiently especially in elevator systems, where space is tight and ventilation is limited. Overheating can shorten lifespan, trigger faults, or even create safety hazards. That’s why I always pay close attention to thermal performance and energy efficiency during transformer selection.

Elevator systems often operate in enclosed shafts or machine rooms with little to no airflow. To prevent overheating, I recommend transformers with high-efficiency core materials and insulation systems rated Class F or Class H. These insulation classes allow the transformer to safely handle higher internal temperatures, extending life and maintaining stable output under load.

Low idle losses are also critical. In standby mode, when the elevator is not moving, the transformer is still energized. A high idle loss can waste energy and generate unnecessary heat. Choosing a transformer with low no-load losses helps improve energy efficiency, especially in systems that run continuously.

In more demanding applications like high-rise buildings, outdoor installations, or regions with extreme temperatures I often specify potted or encapsulated transformers. These provide better thermal dissipation and protect against moisture, vibration, and dust. In some cases, forced ventilation or heat sinks may also be required to maintain safe operating temperatures.

Finally, always include built-in overtemperature protection, such as thermal fuses or resettable protectors. This helps prevent damage in case of overload or ventilation failure.

Optimizing for thermal and energy performance not only boosts reliability but also ensures your elevator system operates safely and efficiently in any environment.

Step 5: Assess Environment and Reliability

After nailing down thermal and efficiency specs, evaluating the real-world environment and planning for long-term reliability ensures your elevator transformer withstands years of abuse without unplanned failures or service calls. This step tailors the design to shaft conditions, vibration loads, and maintenance realities for maximum uptime in a 24/7 safety-critical system.

Evaluating Ambient Conditions in Shafts and Machine Rooms

Elevator environments are brutal, with heat buildup, dust, and confined spaces stressing components relentlessly.

- Machine rooms often hit 40-50°C from VFDs and motors, while shafts trap heat and humidity, swinging from -10°C winters to 60°C+ summers in high-rises.

- Vibration from hoist cables, doors, and seismic activity (up to 5G in some codes) combines with oil mist and grit, accelerating wear on unprotected windings.

Map these factors site-by-site urban high-rises differ vastly from rural service elevators—to spec insulation, sealing, and mounting accordingly.

Vibration-Resistant Designs with Potting or Encapsulation

Standard transformers fail fast under elevator shake; ruggedized builds are essential for longevity.

- Fully potted or epoxy-encapsulated units lock windings and cores in place, resisting 10-20G vibration and preventing micro-cracks or loosening over millions of cycles.

- Soft-mount isolators or rubber-bonded cores further dampen resonance, critical near passenger areas to avoid hum amplification.

Opt for these in traction or hydraulic systems where door slams and emergency stops generate constant shock loads.

Planning for Service Life and Maintenance Access

Elevators demand 20-30+ year lifespans with minimal intervention, so design for “fit and forget” reliability.

- Select components rated for 100,000+ hours MTBF with Class H insulation and oversized headroom to counter aging from thermal cycling and harmonics.

- Prioritize accessible terminations (front-panel terminals over buried leads) and modular mounting for quick swaps without full panel disassembly during annual inspections.

Document test data like temperature rise curves and vibration quals to satisfy insurers and regulators like ASME A17.1 or EN 81.

Step 6: Prioritize Safety Certifications and Protections

When selecting a transformer for elevator applications, I always recommend choosing models that are UL-listed and CE-marked, and fully compliant with relevant elevator safety standards such as EN 81 in Europe or ASME A17.1 in North America. These certifications confirm that the transformer has been tested and approved for use in regulated environments.

The transformer should include reinforced insulation systems that prevent electrical breakdown even under stress, and thermal fuses or temperature sensors to shut down safely in case of overheating. These features help protect both the transformer and connected systems from damage.

To further enhance safety, it’s important to include overcurrent protection, grounding paths, and fault-tolerant designs especially for transformers that are part of emergency power circuits. These safety measures ensure that the elevator remains operational during power disruptions or fault conditions, minimizing risk to passengers and equipment.

Finally, make sure the transformer is hi-pot tested to verify insulation strength under high voltage. This testing is essential for confirming long-term electrical safety and reducing the chance of field failure.

By prioritizing safety and certifications from the start, you not only meet compliance requirements you build trust in the reliability and professionalism of your elevator system.

Step 7: Customization and Supplier Support

Elevator control systems are not off-the-shelf they’re engineered solutions tailored to specific building layouts, safety features, and performance requirements. The same should apply to your transformer. That’s why choosing a supplier who offers customization and hands-on engineering support is essential for a smooth and successful integration.

Elevator applications often demand more than a standard transformer. At Unicreed, we regularly help customers specify non-standard voltage outputs, dual primary windings for international use, multi-secondary configurations for powering control logic and auxiliary systems independently, and custom taps to fine-tune voltage ranges within the same unit.

This level of flexibility ensures your transformer works seamlessly with advanced control logic, sensor arrays, and power management strategies without requiring external adaptations or rework.

Equally important is the support behind the product. A responsive supplier who offers fast prototyping, design validation, and technical collaboration can dramatically reduce design cycles, prevent late-stage integration issues, and speed up your time to market.

At Unicreed, I work directly with engineers to translate technical requirements into transformer designs that are electrically accurate, mechanically compatible, and compliantly certified so your elevator system performs exactly as intended, from installation through long-term operation.

Conclusion

Choosing the right transformer for an elevator control system isn’t just about matching voltage and power. It’s about ensuring safety, continuous operation, and long-term reliability in a critical application that runs 24 hours a day. A well-selected transformer helps prevent unexpected downtime, improves energy efficiency, and ensures compliance with industry standards.

At Unicreed, I work closely with clients to deliver custom transformer solutions that are precisely engineered to fit elevator environments whether that means compact mounting, quiet operation, or built-in protection features. Our transformers are trusted in elevator systems worldwide because they’re built with real-world performance in mind.

If you’re designing or upgrading an elevator system and need a transformer that fits perfectly, performs reliably, and meets safety standards, I invite you to reach out to Unicreed. Let’s work together to build a solution tailored to your system.