Choosing the right core material for a toroidal transformer can feel like navigating a complex maze. I know from experience how challenging it is to decide between different core options, especially when faced with terms like A Standard and B Standard cores. The core material isn’t just a technical detail, it profoundly impacts transformer efficiency, heat generation, physical size, and ultimately the cost of production and operation.

The wrong choice can lead to excessive energy losses, overheating problems, bulky designs, or inflated costs that eat into project budgets. On the other hand, selecting the optimal core material improves performance, extends lifespan, and makes integration into your system much smoother.

In this blog, I will break down the key differences between A Standard and B Standard toroidal transformer cores. My goal is to help you make an informed choice, ensuring your transformer meets your efficiency, space, and budget requirements without compromise.

What Are A Standard Core in Toroidal Transformer?

A Standard Core in a toroidal transformer typically refers to a core made from laminated silicon steel, also known as electrical steel. This material consists of very thin strips of silicon steel that are laminated together to reduce eddy current losses, which are a major source of energy inefficiency in transformers.

Key physical and magnetic properties of A Standard cores include high magnetic permeability, which allows efficient magnetic flux conduction, and low core losses due to the lamination process that inhibits eddy currents. These cores offer good efficiency in typical power distribution applications while maintaining manageable heat generation.

A Standard cores are widely used in various applications such as power supplies, electric motors, and household or industrial electrical equipment. Their benefits include reliable performance, cost-effectiveness, and standardized manufacturing that meets most general-purpose transformer needs. They provide a solid balance between efficiency, size, and price, making them a popular core choice in toroidal transformers.

What Are B Standard Core in Toroidal Transformer?

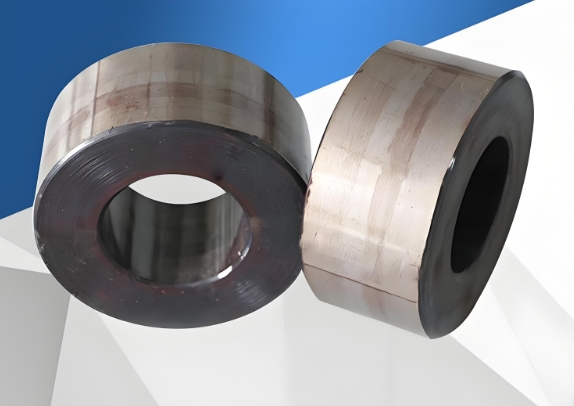

B Standard Core in Toroidal Transformers typically refers to cores made from materials such as powdered iron, amorphous steel, or other specialized alloys. These materials differ from the conventional laminated silicon steel of A Standard cores by offering enhanced magnetic and physical properties suited for specific performance needs.

Key characteristics of B Standard cores compared to A cores include lower core losses, especially due to the unique atomic structure of amorphous steel or the granular nature of powdered iron. These materials generally have higher magnetic permeability and reduced hysteresis losses, which translates into improved transformer efficiency and less heat generation. They also often allow for more compact designs because they can operate effectively at higher flux densities.

Common applications for B Standard cores include high-efficiency power supplies, renewable energy systems, audio equipment, and precision medical devices where minimizing energy loss and noise is critical. The advantages of B Standard cores typically involve increased efficiency, reduced operational costs, and enhanced performance in demanding environments albeit often at a higher material and manufacturing cost than A Standard cores.

Comparative Analysis Between A and B Standard Core Materials

To make the best choice in toroidal transformer design, it’s essential to look beyond general specifications and examine how different core materials actually perform in practice. While both A Standard and B Standard cores may meet basic requirements, their characteristics can lead to very different outcomes depending on your specific application. Whether you’re aiming for maximum efficiency, lower heat generation, or a more compact design, understanding the real-world trade-offs is key. Let’s now take a closer look at how these two core materials compare in terms of performance, cost, and suitability.

Here is a comparative analysis between A Standard and B Standard core materials for toroidal transformers in table form:

| Feature | A Standard Core (e.g., Laminated Silicon Steel) | B Standard Core (e.g., Powdered Iron, Amorphous Steel) |

| Material Description | Thin strips of silicon steel laminated to reduce eddy current losses | Powdered iron pressed into core or non-crystalline amorphous alloys |

| Magnetic Permeability | High | Generally higher, allowing operation at higher flux densities |

| Core Losses | Low but higher than amorphous or powdered cores | Significantly lower, reducing hysteresis and eddy current losses |

| Efficiency | Good efficiency (typical) | Higher efficiency, especially at low loads |

| Heat Dissipation | Moderate heat generation | Lower heat generation due to reduced losses |

| Size and Weight | Larger and heavier | Can be more compact and lighter due to better magnetic properties |

| Noise Levels | Moderate noise, some vibration | Lower noise and vibration due to uniform core structure |

| Typical Applications | General power supplies, motors, appliances | High-efficiency power supplies, renewable energy, audio, medical |

| Cost | More cost-effective, widely available | Typically higher material and manufacturing cost |

| Manufacturing Complexity | Standard lamination and winding processes | More complex, sometimes requiring special handling for amorphous cores |

How does the core material influence transformer lifespan?

The lifespan of a transformer is heavily influenced by the materials used in its construction, particularly the core material. The core is central to magnetic flux transfer, and its physical and magnetic properties affect energy loss, heat generation, and mechanical stability all of which impact durability and longevity. Higher core losses translate into more heat, accelerating insulation aging and reducing transformer life. Conversely, advanced core materials with lower losses and better thermal performance help maintain lower operating temperatures, extending transformer lifespan. The choice between standard laminated silicon steel cores (A Standard) and specialized materials like amorphous steel or powdered iron (B Standard) significantly affects these factors. Understanding how core material governs heat dissipation, efficiency, and mechanical stress resilience is key to maximizing transformer life, reducing maintenance, and ensuring reliable operation over many years.

Does core material influence EMI or RFI performance?

Yes, core material significantly influences a transformer’s electromagnetic interference (EMI) and radio-frequency interference (RFI) performance. Materials with higher magnetic permeability, such as silicon steel or amorphous metals, allow more efficient magnetic flux conduction, which reduces stray magnetic fields that cause EMI. Additionally, core materials with low hysteresis and eddy current losses limit the generation of unwanted electromagnetic noise. For example, amorphous and nanocrystalline cores are known for their superior EMI suppression across a broad frequency range due to their fine magnetic structure and reduced losses. The shape and construction of toroidal cores further support this by containing magnetic flux within the core, minimizing external EMI radiation compared to conventional cores. Thus, choosing the right core material and design is crucial in minimizing EMI/RFI emissions, ensuring reliable transformer operation, and maintaining compliance with electromagnetic compatibility (EMC) standards.

How do core materials affect noise levels in operation?

Core materials significantly affect noise levels during transformer operation primarily due to a phenomenon called magnetostriction, where the core material physically expands and contracts as it magnetizes and demagnetizes. Materials with lower magnetostrictive properties, such as high-grade grain-oriented silicon steel, amorphous steel, or nanocrystalline alloys, generate less mechanical vibration and thus less audible noise.

Additionally, core loss characteristics including hysteresis and eddy current losses impact heat generation and magnetic forces within the core, both of which can contribute to noise. Cores made from materials that minimize these losses reduce internal stresses and vibrations, lowering the acoustic signature.

Manufacturers also use strategies like precision lamination stacking, tight clamping, and specialized coatings to reduce core vibration. Toroidal core designs inherently reduce noise by maintaining a continuous magnetic path with fewer joints, leading to less vibration compared to traditional laminated E-I cores.

How to Choose the Right Core for Your Application?

electing the optimal core material is critical to achieving the best performance, efficiency, durability, and compliance for your custom waterproof transformers, especially when noise reduction and safety are priorities. Here are 5 ways to help you confidently choose the right core for your specific needs:

1.Identify Your Application Requirements

Operating Frequency: Some core materials excel at low frequencies (e.g., silicon steel for power distribution), while others like ferrite or nanocrystalline perform better in high-frequency scenarios such as switching power supplies or EMI-sensitive circuits.

Power Rating & Load Profile: Consider whether your transformer will run at full load continuously or variable loads, as this affects core loss and thermal management needs.

Space & Weight Constraints: For compact designs or weight-sensitive installations, lean toward higher-permeability materials or amorphous cores, which can provide the same performance in a smaller, lighter package.

Environmental Demands: For waterproof, outdoor, or vibration-prone settings, prioritize materials and construction techniques that offer superior corrosion resistance and structural robustness.

2.Compare Core Material Properties

| Core Material | Frequency Range | Losses | Noise (Magnetostriction) | Size/Weight | Typical Applications |

| Laminated Silicon Steel | Power, Low-Frequency | Low-Medium | Medium | Standard | Power distribution, industrial power |

| Powdered Iron | Low-Mid Frequency | Medium | Medium | Medium | Chokes, filters, moderate cost transformers |

| Amorphous Steel | Low-Mid Frequency | Very Low | Low | Small/Lighter | High-efficiency, noise-sensitive equipment |

| Ferrite | High-Frequency | Low (at HF) | Low | Light | High-frequency converters, EMI filters |

| Nanocrystalline | Wide (HF & LF) | Lowest | Lowest | Smallest | Premium power electronics, medical, audio |

- Efficiency: Aim for core materials with minimal hysteresis/eddy losses if energy efficiency and long-term operating costs are priorities.

- Noise Reduction: If your design focus is low acoustic and electromagnetic noise, prioritize amorphous or nanocrystalline materials, and select a toroidal geometry whenever feasible.

- Thermal Performance: Higher thermal conductivity ensures better heat dissipation, critical in waterproof or sealed transformers.

3.Safety and Compliance Considerations

Voltage Stress: High-voltage applications demand materials with proven dielectric and mechanical strength.

Certifications: For medical, marine, or industrial use, verify that the core material and assembly comply with required industry certifications and tests.

4.Consult with Manufacturers

Leverage your manufacturer’s material expertise and request custom designs tailored to your safety, efficiency, and noise reduction needs.

Share all relevant details application, expected environment, target dimensions, and any unique compliance or durability requirements.

5.Practical Recommendations

For General Purpose/Power Transformers: Laminated silicon steel offers a cost-effective, reliable solution.

For High-Efficiency, Noise-Sensitive Designs: Amorphous or nanocrystalline cores, ideally in toroidal form, deliver the best mix of efficiency, size, and noise suppression.

For High-Frequency/EMI Applications: Ferrite cores are usually the top choice.

How Unicreed Supports Core Material Selection?

At Unicreed, I work closely with engineers and purchasing teams to ensure you get more than just a transformer,you get the right transformer for your application. When it comes to core material selection, here’s how we support you:

1.Expert Consultation

We help you evaluate the technical requirements of your design,load, frequency, size constraints, heat tolerance, and budget and recommend whether an A Standard or B Standard core fits best.

2.Custom Design Services

Whether you’re building compact medical devices or heavy-duty industrial control systems, we offer fully customizable toroidal transformers with core materials tailored to your performance goals.

3.Material Sourcing and Testing

We source high-quality core materials from trusted global suppliers and provide test data to verify magnetic performance, thermal behavior, and regulatory compliance.

4.Prototyping and Sampling

Need to compare A and B cores in your setup? We can provide samples for side-by-side evaluation, speeding up your decision-making and design approval.

Conclusion:

After working with both A Standard and B Standard cores in toroidal transformers, I can confidently say the difference can be quite significant depending on your design requirements. Whether you need better energy efficiency, lower heat generation, or a more compact size, the right core material can make a big impact.

That’s why I always recommend making an informed choice. Understanding your specific needs and how each core performs will help you avoid costly adjustments later and improve your overall system performance.

At Unicreed, we focus on helping engineers and manufacturers like you select the most suitable core material for your application. We offer a wide range of toroidal transformers and can provide customized designs tailored to your size, efficiency, and thermal needs. If you’re not sure which core material is right for you, feel free to contact us at sales@unicreed-transformer.com or visit www.unicreed-transformer.com. We’re here to help you build better.