Have you ever worried about what might happen if a transformer accidentally falls during handling? A transformer is a delicate and critical component, and even a minor drop can cause hidden internal damage, compromise insulation, or lead to dangerous faults. Ignoring these risks could result in performance issues, electrical failures, or even safety hazards.

That’s why acting fast with a thorough inspection is so important. By knowing exactly what to check, you can prevent further damage, avoid costly repairs, and ensure the transformer remains safe to use.

In this guide, I’ll walk you through a clear step-by-step checklist to assess a transformer after it falls. Whether you’re a technician, buyer, or end-user, this practical advice will help you make informed decisions and protect your equipment.

Why Dropping a Transformer is a Serious Issue

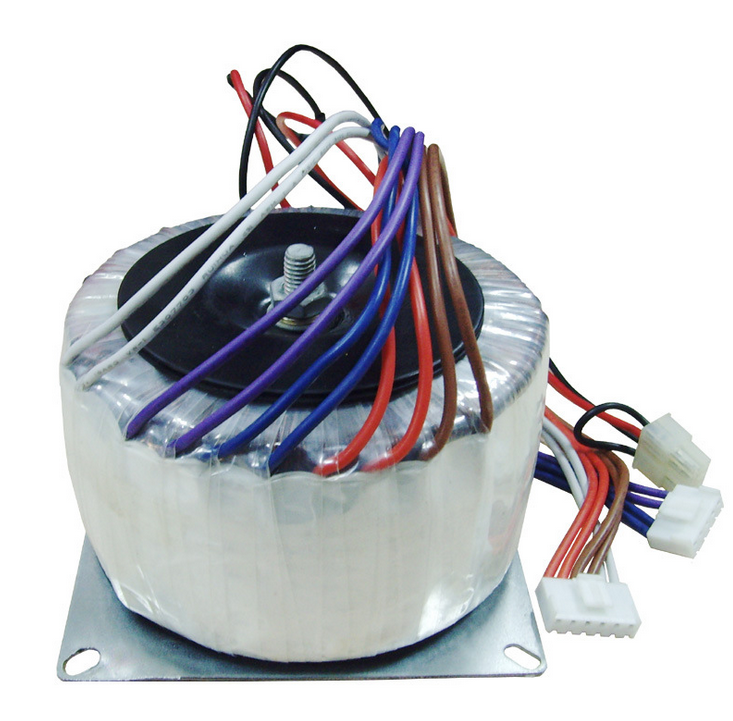

Transformers are precision- ngineered devices made up of sensitive components like windings, cores, and insulation materials. These parts work together to ensure safe and efficient energy transfer. When a transformer falls to the ground, the impact can compromise these delicate elements, even if there’s no obvious external damage.

Common issues caused by a fall include misaligned cores, deformed windings, cracked insulation, or loosened internal connections. These problems may not be visible at first but can lead to reduced efficiency, overheating, or even dangerous short circuits when the transformer is energized again.

Using a damaged transformer without a proper inspection poses significant risks. It can cause unexpected equipment failure, costly downtime, or in severe cases, fire and electrical hazards. That’s why every dropped transformer should be treated as a serious event requiring immediate evaluation.

What immediate actions should you take after a transformer falls?

Before you begin inspecting a transformer that has fallen, it’s important to take the right steps to ensure both your safety and the integrity of the equipment. A transformer may look undamaged from the outside, but internal components like windings, cores, or insulation could have been compromised by the impact. Acting carefully in the first moments after a fall can help prevent further damage and avoid potential hazards. So, what immediate actions should you take to handle this situation properly?

1.Prioritize Safety First

Before you touch or move the transformer, make sure the power is completely disconnected. Even if the transformer appears intact, internal damage can create hidden electrical hazards.

2.Check for Visible Damage

Inspect the casing, terminals, and mounting brackets carefully. Look for cracks, dents, bent pins (for PCB transformers), or oil leaks (if it’s oil-filled). Do not attempt to power it on at this stage.

3.Handle With Care

If you need to move the transformer, do so gently to avoid further stress on the core and windings. Place it on a stable, vibration-free surface.

4.Isolate the Unit for Testing

Tag the transformer as “Do Not Use” until it has been properly inspected and tested by a qualified technician.

5.Plan a Thorough Inspection

Prepare for electrical and mechanical testing (continuity check, insulation resistance, etc.) before deciding whether it can be reused.

What Are the Key Areas to Inspect?

Once you’ve taken the immediate safety steps after a transformer falls, the next critical task is to perform a thorough inspection. Even if there’s no visible damage, the impact may have affected internal components or weakened the structure in ways that aren’t obvious at first glance. Knowing exactly where to look helps you identify potential issues early and prevent costly failures later. So, what are the key areas you should focus on during your inspection?

After a transformer falls, a thorough inspection is critical to identify any potential damage. Focus on these 3keys areas:

1.External Damage

Start by examining the transformer’s exterior. Check the casing, terminals, and mounting brackets for any cracks, dents, or deformation. Look carefully for signs of oil leakage or damage to protective coatings, as these could indicate internal issues.

2.Internal Damage (if possible)

If safe and feasible, gently shake the transformer and listen for any loose components inside. This may point to dislodged windings or hardware. To further assess internal integrity, perform an insulation resistance test to detect faults that aren’t visible from the outside.

3.Electrical Tests

Before re-energizing the unit, carry out electrical tests. Use a Megger to check insulation resistance and ensure it meets specifications. Also, perform continuity and winding resistance checks to verify that no circuits are open or shorted.

When to Consult an Expert?

While some minor issues can be identified through a basic inspection, not all damage from a transformer fall is visible or easy to diagnose. Hidden problems like winding displacement, core misalignment, or insulation failure often require specialized tools and expertise to detect. This is why knowing when to involve a professional is just as important as doing the initial checks yourself. So, when exactly should you consult an expert?

There are situations where a visual inspection and basic tests are not enough to ensure the transformer’s safety and performance. If you suspect internal issues like winding displacement or core misalignment, it’s time to bring in professionals. These problems require advanced diagnostic tools and expertise that go beyond routine checks.

Factory inspection or repair services are also critical when the transformer shows signs of serious damage, such as unusual noises, insulation failures, or oil leaks. Experts can perform detailed testing, disassemble the unit safely if needed, and provide certified repairs to restore it to reliable working condition.

By consulting a professional early, you can avoid costly downtime, prevent further damage, and ensure your transformer operates safely and efficiently.

How to Implement Preventive Measures for Future Handling?

Understanding what to check after a transformer falls is crucial, but prevention is always better than cure. By adopting the right handling practices and transport precautions, you can significantly reduce the risk of accidents and protect your equipment from damage. So, how can you implement preventive measures to ensure safe handling and avoid transformer falls in the future?

To prevent accidents like a transformer falling in the future, it’s essential to adopt proper handling and transport practices.

Safe Handling Practices

Always use the correct lifting equipment such as hoists, slings, or forklifts designed for the transformer’s weight and size. Ensure that trained personnel handle the unit and follow safety protocols to avoid tilting or dropping during installation or maintenance.

Packaging and Transport Tips

When preparing a transformer for transport, use robust packaging that protects against shocks and vibrations. Secure the transformer firmly on pallets or crates, and avoid stacking heavy items on top of it. During shipping, make sure the unit is properly strapped and cushioned to prevent movement or impact.

What Are the Preventive Tips to Avoid Transformer Falls?

After learning how to handle and inspect a transformer following a fall, it’s equally important to focus on prevention. Taking proactive steps during handling, transport, and installation can minimize the chances of such accidents happening in the first place. So, what practical tips can help you avoid transformer falls and keep your equipment safe?

Preventing a transformer from falling starts with proactive measures during handling, transport, and installation. Here are three essential tips:

1.Regular Maintenance and Inspection Routines

Establish routine checks to ensure all mounting hardware, brackets, and support structures are secure. Identifying weak points early can help avoid accidents during operation or relocation.

2.Proper Handling and Unloading Procedures

Always follow standard procedures when lifting or moving transformers. Use appropriate lifting equipment like cranes, forklifts, and slings, and ensure trained personnel are supervising unloading and installation activities.

3.Use of Fall Protection and Load Securing

During transport, secure the transformer with straps and braces to prevent shifting. For installations at height, implement fall protection systems such as guard rails or safety nets to minimize risks if the unit slips.

By following these preventive tips, you can greatly reduce the chances of transformer falls and protect both your equipment and personnel.

Conclusion

When a transformer falls, even a small impact can create serious internal and external issues that aren’t always visible at first glance. That’s why I believe an immediate and thorough inspection is critical to ensure the transformer’s reliability and prevent potential failures down the line.

At Unicreed, we specialize in transformer testing, repair, and custom solutions to help you handle these challenges with confidence. If you’re unsure about the condition of your transformer after a fall, don’t take risks reach out to us for expert support and peace of mind.

Contact us today to get professional advice and protect the performance and safety of your equipment.