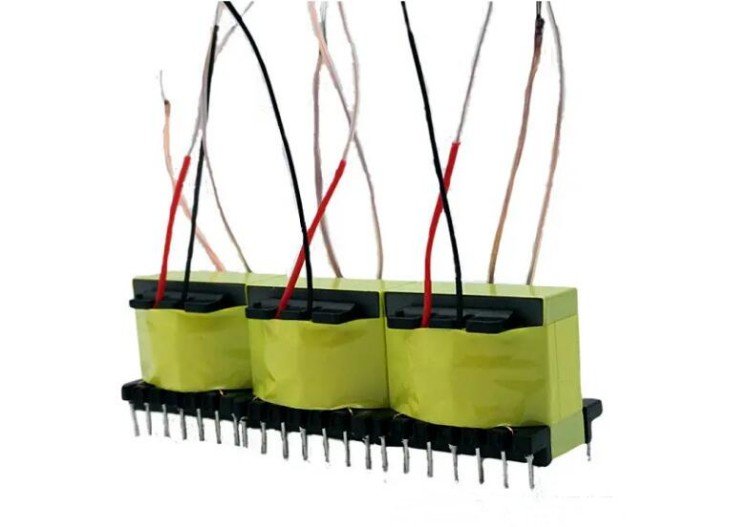

A high-frequency transformer is a widely used electronic component in modern technology. Besides transforming the input voltage into output voltage, it also performs signal isolation and power matching. Flying leads are commonly used to lead out high-frequency transformers, so why should high-frequency transformers use flying leads? I have written an article that will help you to find an answer to your question.

Why use flying wire for high frequency transformer lead-out?

1.High Frequency Current Characteristics

One of the factors to be considered is the characteristics of high-frequency current. High frequency current has the following characteristics in comparison with low frequency current:

- High-frequency current has a short transmission distance: the transmission distance of high-frequency current in the circuit is shorter than that of low-frequency current, since high-frequency current will encounter problems such as impedance and inductance during transmission, which results in energy loss.

- High-frequency current has a different conduction mode: High-frequency current has a different conduction mode from low-frequency current, since the higher the frequency of high-frequency current, the more inclined its conduction mode is to the propagation mode of electromagnetic waves. For this reason, high-frequency circuits require consideration of factors such as resistance, inductance, and capacitance to ensure their stability and performance.

- There is a danger of eddy currents in high-frequency currents: The high frequency currents tend to generate eddy currents in the conductors, which results in energy loss and heat generation, affecting the circuit’s performance and life.

Considering the above characteristics, we can conclude that high-frequency current will result in many unfavorable factors in the circuit that will adversely affect its performance and stability. To solve these problems, some special measures must be taken when designing and manufacturing high-frequency transformers

2.High Frequency Transformer design

It is also necessary to consider the design requirements of high-frequency transformers. The following requirements must be taken into account when designing and manufacturing high-frequency transformers:

- Matching performance is good:To ensure that the input voltage can be converted correctly to the output voltage, and to accomplish functions such as signal isolation and power matching, high-frequency transformers need to have good matching capabilities.

- Low loss and high efficiency:Transformer designs and manufacture must take into account the requirements for high efficiency and low loss to avoid problems related to energy loss and heat generation.

- Adapt to different circuit arrangements and working conditions:For high-frequency transformers to perform and remain stable, different circuit arrangements and working environments need to be considered.

- Ability to resist interference:High-frequency circuits are sensitive to external interference, so high-frequency transformers must possess certain anti-interference capabilities in order to function normally.

- Lightweight and small in size:Electronic equipment usually uses high-frequency transformers, so they have to be small and light in order to meet the design requirements.

Due to the limitations of space and the skeleton itself, safety regulations allow the distance of the flying wire to be extended to meet the safety distance requirement when developing products to achieve small size or low height. The lead wires are generally secondary. If the legs are directly hung, the primary and secondary cannot meet the high voltage requirements to increase the safety distance.

The advantage of using flying leads for high-frequency transformers?

Flying leads are used in high-frequency transformers because high-frequency currents generate eddy currents in the circuit, which lead to high-frequency losses and heat. Therefore, in order to reduce these losses, high-frequency transformer coils typically use thin wires, but the diameter of these thin wires is small, so if they are directly soldered to the PCB, short circuits are easily caused.

Flying wires can be used to solve this problem effectively. Short circuits and other unnecessary contacts between the coil and the PCB board can be avoided by using thin and flexible wire to lead out the coil, while at the same time, it can better adapt to the circuit layout requirements. Additionally, the flying lead length can be adjusted to meet the high-frequency transformer’s design and installation requirements.

Flying leads can therefore be used to lead out the coil of a high-frequency transformer, thereby reducing the heat generated by the high-frequency transformer, while also improving its adaptability to the circuit’s design and layout requirements.