In my experience working with OEMs and industrial system builders, I’ve learned that a one-size-fits-all transformer often doesn’t cut it. The demands of modern systems, whether in medical devices, control panels, or smart meters, require precision, reliability, and seamless integration. When a standard off-the-shelf transformer doesn’t meet those needs, it can delay production or compromise performance.

I’ve seen firsthand how small mismatches in voltage, mounting, or wiring can become major headaches. That’s why I rely on Unicreed, a transformer manufacturer with over 13 years of experience, to deliver customized solutions that fit perfectly from day one.

At Unicreed, we specialize in tailoring transformers to your exact requirements. From electrical specifications to mechanical design and international compliance, we build each unit to match your system. If you’re looking for a transformer that’s built for your application, not just close to it, this post will show you five key ways we make that happen.

At Unicreed, we understand that every system has unique electrical, mechanical, and regulatory demands. That’s why we don’t believe in one-size-fits-all transformers. Instead, we work closely with OEMs and engineers to develop solutions that are precisely tailored to the real-world needs of their products.

In this blog, I’ll talk you through the five core ways Unicreed customizes transformers to ensure better integration, performance, and reliability:

- Way 1: Custom Voltage and Current Ratings

- Way 2: Mechanical Design and Form Factor

- Way 3: Thermal, Efficiency, and Noise Performance Tuning

- Way 4: Safety, Compliance, and Reliability Engineering

- Way 5: Application-Specific Features and Integration Support

These five areas form the foundation of our transformer customization process and they’re what make Unicreed a trusted partner for mission-critical and high-performance applications.

Way 1: Custom Voltage and Current Ratings

When I start a new project, one of the first things I look at is the voltage and current requirements. Getting these right is critical, and I’ve learned that relying on standard transformer specs can lead to unnecessary compromises. That’s why I turn to Unicreed when I need precision.

At Unicreed, we tailor the primary and secondary voltages to match your specific system and the regional mains standards you operate in. Whether your input voltage is 120 volts at 60 hertz or 230 volts at 50 hertz, we make sure the transformer is designed to handle it accurately. On the output side, we customize the secondary voltage and current ratings to support your actual load—no more overrating or underrating.

We also match the VA power rating to your real-world usage, with the right headroom for surges and future scalability. This kind of customization improves voltage regulation, reduces heat buildup, and increases the overall reliability of your system. Compared to off-the-shelf solutions, our approach eliminates the waste and risks that come from using generic, one-size-fits-all transformers. It is a smarter, safer, and more efficient way to build.

Way 2: Mechanical Design and Form Factor

Even if a transformer meets all your electrical specs, it still has to physically fit into your design. Space is often tight especially in compact control systems, smart devices, or medical equipment. That’s why mechanical customization is just as important as electrical performance. At Unicreed, we ensure our transformers are built to fit your enclosure, mounting setup, and wiring layout perfectly.

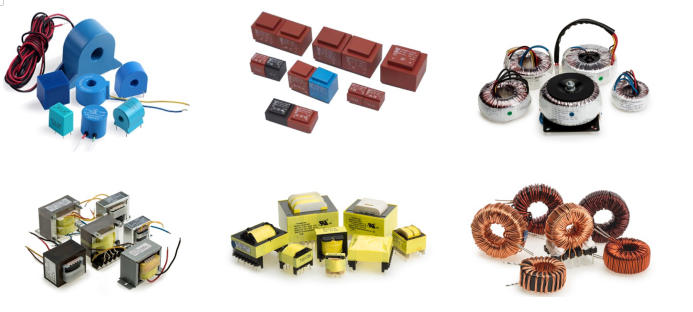

At Unicreed, we offer a wide range of custom form factors including toroidal, EI core, UI core, and encapsulated designs to match the mechanical constraints of your system. Whether you need a low-profile unit for a flat housing, a fully sealed transformer for rugged environments, or a lightweight open-frame design, we tailor each model accordingly.

We also support various mounting styles:

- PCB mount for compact circuit board integration

- Chassis mount or baseplate options for larger power modules

- Bracketed designs for secure, vibration-resistant installations in harsh or mobile environments

In addition, we customize lead types and terminations to simplify wiring during assembly. Options include:

- Flying leads with specific lengths and insulation types

- Lugs and terminals for quick connect/disconnect

- Pinouts for direct PCB soldering or connector-based systems

By aligning the mechanical design with your product’s layout, we help reduce assembly time, avoid fitment issues, and improve long-term reliability. This kind of customization makes integration smoother especially for OEMs working under tight space and performance constraints.

Way 3: Thermal, Efficiency, and Noise Performance Tuning

While electrical and mechanical customization gets the transformer into your system, fine-tuning its thermal, efficiency, and noise characteristics ensures it performs reliably without generating excess heat, waste, or interference. Unicreed optimizes these aspects by selecting the right materials and construction techniques tailored to your application’s demands.

Core Materials and Winding Strategies for Efficiency

Unicreed chooses high-grade core materials and winding approaches to minimize losses and control temperature rise under your specific load conditions.

Grain-oriented silicon steel or advanced amorphous/nanocrystalline cores reduce hysteresis and eddy current losses, boosting efficiency especially at partial loads or in always-on systems.

Optimized winding layouts such as interleaved layers, bifilar windings, or sectionalized coils lower copper resistance (I²R losses) and improve coupling between primary and secondary, resulting in tighter voltage regulation and less idle power draw.

These choices keep the transformer running cooler, extend insulation life, and reduce energy costs over time, particularly in high-volume or continuous-duty applications.

Insulation Classes for Thermal Management

Insulation class selection directly impacts how much temperature rise the transformer can safely tolerate in your environment.

- Options range from Class A (105°C) for cost-sensitive, low-ambient designs to Class H (180°C) or higher for hot enclosures, industrial ovens, or high-reliability military/aerospace use.

- Enhanced impregnation, vacuum pressure processes, and higher-grade enamels provide better thermal conductivity and resistance to humidity or chemical exposure.

By matching insulation to expected ambient temperatures, ventilation, and duty cycle, Unicreed ensures the transformer stays within safe limits, avoiding premature aging or de-rating penalties.

Low-Noise and Low-Hum Designs

For sensitive applications like audio amplifiers, medical devices, or precision instrumentation, Unicreed incorporates specialized features to suppress both mechanical hum and electrical noise.

- Tighter core winding gaps, precise lamination stacking, and potting compounds dampen magnetostriction-induced vibration, virtually eliminating audible hum even at full load.

- Electrostatic shields between windings, Faraday cages, or mu-metal enclosures block capacitive coupling and EMI/RFI, preserving signal integrity in high-fidelity or low-noise environments.

These low-noise optimizations make Unicreed transformers ideal for hi-fi systems, patient monitors, lab equipment, or any setup where quiet operation and clean power are non-negotiable.

Way 4: Safety, Compliance, and Reliability Engineering

In critical applications, safety and compliance are non-negotiable. Whether I am building systems for industrial control, medical devices, or global export, I need to know that every component meets the required standards. This is where Unicreed’s engineering approach gives me real peace of mind.

Unicreed offers customization to meet specific international standards and market regulations, including CE, UL, ROHS, VDE, and CQC. We adjust design parameters like creepage and clearance distances, insulation systems, and protective components to ensure compliance with safety norms such as EN61558, UL1585, and IEC 60950.

For example, if a project requires reinforced insulation, Class B or F materials, or integrated thermal fuses, Unicreed incorporates those directly into the design. This ensures the transformer will operate safely, even in harsh or sensitive environments.

To support long service life and high reliability, every transformer goes through strict testing and quality control. This includes hi-pot (dielectric strength) testing, burn-in procedures, and visual and functional inspections. Only units that pass all checkpoints move forward.

When I work with Unicreed, I am confident that the transformers are not just built to perform they are built to last and comply, reducing the risk of field failures and protecting the reputation of my end product.

Way 5: Application-Specific Features and Integration Support

The final way Unicreed elevates your transformer from a generic component to a seamless system enabler is through application-specific features and hands-on engineering support that anticipates your unique challenges and accelerates integration.

Application-Focused Customization Options

Unicreed incorporates targeted features that directly address the nuances of your end-use, ensuring optimal performance without extra circuitry or compromises.

- Multiple isolated outputs allow separate power rails for analog, digital, and control sections, minimizing crosstalk and enabling compliance with safety isolation requirements in medical or industrial gear.

- Electrostatic shields between primary and secondary windings reduce capacitive coupling and common-mode noise, which is crucial for high-fidelity audio, precision instrumentation, or EMI-sensitive environments.

- Custom taps on windings provide selectable voltages (e.g., 12/15/18 V) for flexible regulation or multi-stage power supplies, while integrated fusing or thermal cutouts add inherent protection against overloads or faults.

These options turn the transformer into a “plug-and-perform” solution tailored to applications like renewable energy inverters, EV chargers, or lab power systems.

Engineering Support for Smooth Integration

Unicreed goes beyond parts by partnering with your team through every design phase to ensure flawless system-level fit.

- Specification review: Engineers analyze your schematics, load profiles, and mechanical drawings to recommend optimal features, avoiding over- or under-specification.

- Rapid prototyping: Quick-turn samples with iterative tweaks let you test in-circuit early, refining voltage taps, shielding, or mounting before full production.

- Documentation and handoff: Detailed datasheets, 3D models, wiring diagrams, and test data streamline PCB layout, enclosure design, and certification submissions.

This collaborative approach minimizes redesign loops, cuts time-to-market, and guarantees the transformer enhances rather than hinders your overall system reliability and performance.

Conclusion

From my experience, I know that transformer customization is not just a technical upgrade. It plays a vital role in improving system performance, ensuring safety, and allowing for smooth integration into complex designs. When every detail matters, a custom transformer can make a big difference.

What I appreciate most about working with Unicreed is that we are more than just a parts supplier. We become a partner in your process. We listen carefully, understand your needs, and bring deep industry knowledge to help you get the right solution. That kind of support is hard to find elsewhere.

If you are facing design challenges or need a transformer that truly fits your system, I invite you to connect with us. At Unicreed, we are ready to build exactly what you need, with the precision and care your project deserves.