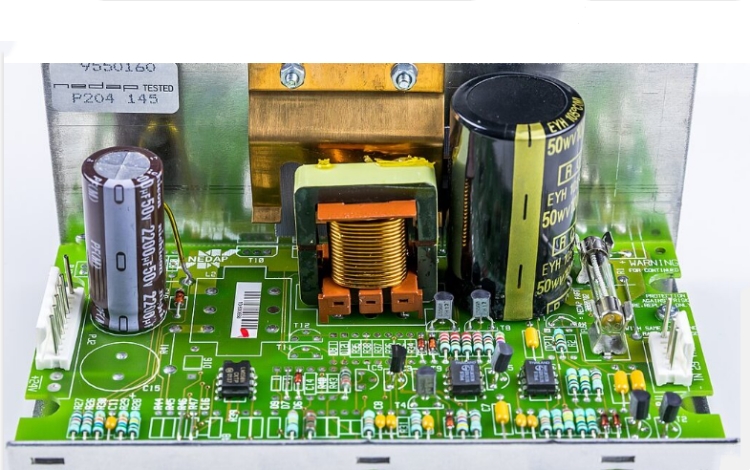

Transformers with switch mode power supplies are crucial parts of electronic devices because they change electrical energy into the voltage needed for the device to operate. These transformers are essential to the operation of many electronic products that we use on a daily basis, such as computers, mobile phones, televisions, and many others. In this blog, we’ll talk about switch mode power source transformers and how crucial it is to keep them from overheating.

5 ways to lower the heating of switch mode power supply transformers

The temperature of switch mode power supply (SMPS) converters can be decreased in a number of ways:

- Improve the magnetic core’s layout: The heating of the transformer can be decreased by using high-quality magnetic core materials, raising the cross-sectional area and shape of the core, and arranging the coils of the core in a sensible way.

- Lower the transformer’s operating frequency: Lowering the transformer’s operating frequency can lessen the amount of alternating magnetizations in the core, which will lower loss and heating.

- Make use of effective cooling structures. For instance, mounting heat sinks, radiators, or fans on the transformer can significantly expand its surface area for heat absorption and speed up the process.

- Decrease the transformer’s current density: Decreasing the transformer’s current density can lessen the loss and heating of the coil, but doing so will also increase the transformer’s volume and weight, which must be weighed in the design.

- Optimize the selection and operating state of the switch tube: Reasonably adjusting the switch tube’s operating parameters and status can lower the switch tube’s heat generation and loss, which lowers the working temperature of the transformer.

Why do switch mode power supply transformers heat up?

Transformers used in switch mode power supplies (SMPS) heat up primarily as a result of losses in the magnetic core and circuit of the transformer.

The magnetization and demagnetization of the core substance brought on by the alternating magnetic field results in magnetic core losses. Hysteresis loss and eddy current loss are produced as a consequence of this process, which raises the core’s temperature.

The resistance of the wire used in the transformer’s helix causes winding losses. Due to the resistance of the wire, some energy is wasted when current flows through it, which causes the wire to heat up.

Additionally, high-frequency noise produced by the SMPS’s switching process has the potential to produce electromagnetic interference (EMI) and induce eddy currents in adjacent conductive materials, including the transformer, which could result in further heating.

How can I tell if the transformer in my switch mode power source is overheating?

If a switch mode power supply (SMPS) transformer is overheating, there are several methods to tell:

Measurement of temperature: The transformer’s temperature can be measured using a thermometer or a thermal camera, which is one of the most straightforward and precise ways. The transformer may be overheating if its temperature rises above the limit for which it is rated.

- Humming noise: A loud humming sound coming from the transformer could mean that the core is overheating and suffering magnetostriction.

- Smell: If the transformer emits a burning or foul-smelling odor, the insulation on the winding may have dissolved from overheating.

- Visual inspection: If the transformer’s wiring or casing appears to be discolored or deformed, this could be a sign that it has been overheated.

The manufacturer’s specifications must be consulted in order to determine the permissible temperature range for the transformer because some transformers are intended to function at high temperatures. It is advised to take immediate action to stop further damage if the transformer is discovered to be overheating, such as decreasing the load or increasing the cooling capacity.

Can I use a bigger ventilation fan to lessen the transformer’s heating?

In order to improve the airflow and cooling capability of the system and lessen transformer heating, a larger cooling fan may be used. It’s essential to remember, though, that sometimes just enlarging the cooling fan won’t be enough to solve the heating problem.

It’s important to take the power usage, noise level, and airflow rate into account when choosing a cooling fan. To adequately chill the transformer, the fan’s airflow rate must be high enough. Additionally, it’s crucial to make sure the airflow is guided toward the transformer and that there are no obstacles in its path.

In addition to using a larger cooling fan, other methods to reduce the heating of the transformer include optimizing the design of the transformer, selecting the appropriate magnetic core material, reducing the current density in the transformer’s winding, and managing the EMI generated during operation. To find the best way to lessen the heating of the transformer in a particular case, it is advised that you speak with a specialist or the transformer’s manufacturer.

Can I use a lesser voltage input to lessen the heating of the transformer?

The heating of the transformer can be somewhat reduced by lowering the incoming voltage. This is so because the core and winding losses of the transformer are inversely proportional to the cube of the input voltage.

In some applications, it might not be preferable to lower the input voltage because doing so might also reduce the transformer’s output voltage and power. Therefore, before using this strategy, it is essential to thoroughly consider how lowering the input voltage will affect the system’s overall performance.

It’s also crucial to keep in mind that if other elements, such as the transformer’s architecture or the cooling system, are causing the heating problem, lowering the input voltage might not be enough to solve it. In these circumstances, it might be essential to employ additional techniques to lessen the transformer’s heating, such as improving its design or boosting its cooling capacity.

How do I select the right magnetic core material to reduce the heating of the transformer?

A key element in lowering a transformer’s heating is selecting the proper magnetic core substance. The size, power level, and frequency of operation of the transformer all affect the choice of magnetic core substance. The following elements should be taken into account when choosing a magnetic core material:

- Core loss: To lessen the heat produced by hysteresis and eddy currents, the magnetic core material should have a minimal core loss. Since the core loss is a function of operating frequency, a material with minimal core loss at the transformer’s operating frequency must be chosen.

- Saturation flux density: To prevent the core from saturating under the circumstances of the transformer’s operation, the magnetic core material should have a high saturation flux density. The performance of the transformer can be impacted if the core saturates because it can result in considerable heating.

- Permeability: To minimize the number of turns needed in the transformer’s winding and corresponding losses, the magnetic core substance should have high permeability.

- Expense: Especially for large-scale production, the expense of the magnetic core material is a crucial factor. The performance of the transformer may be impacted by the lower saturation flux density and greater core loss of cheaper materials.

We have covered several approaches to reducing heating in switch mode power supply transformers, including proper transformer construction and placement, use of appropriate materials, and application of suitable control strategies. When choosing the best method, it is crucial to take the particular application into account because each method has benefits and drawbacks. The switch mode power supply’s efficiency and dependability can be greatly increased with the right method choice. All things considered, by using these techniques, we can lessen the heating in switch mode power supply transformers, improving performance, extending lifespan, and lowering expenses.